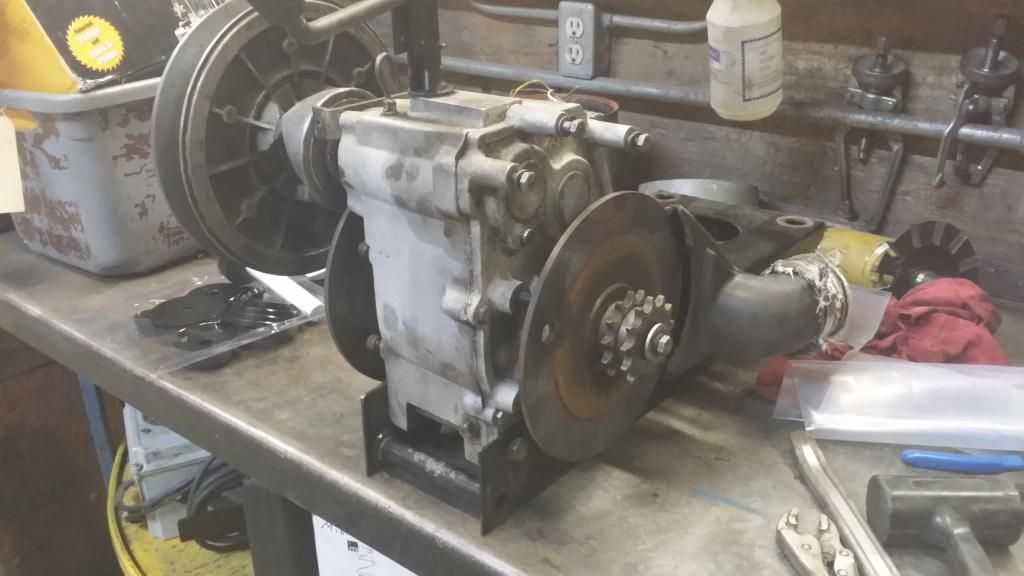

What a pain in my......!!!! Getting that tranny back together was a test of patience. The only really bad thing was the reverse idler shaft. It comes through the cover, and gets a snap ring. This is all fine and dandy if you can get your secondary clutch off, and input shaft out, so you can tap the idler shaft through the hole. No such luck for me. Had to put the tranny cover on the bearing heater so it would slide on easily. Convenient thing is, if you put the bearings on the shafts first, they slip in pretty nicely. Overall it went well, though it took longer than I wanted, and I burned my finger because there was a hole in the glove.

Reply With Quote

Reply With Quote

MUSCA TUR BOTA then eh?

MUSCA TUR BOTA then eh?