Nice to know, i had a thought about the crank, time will say the truth.

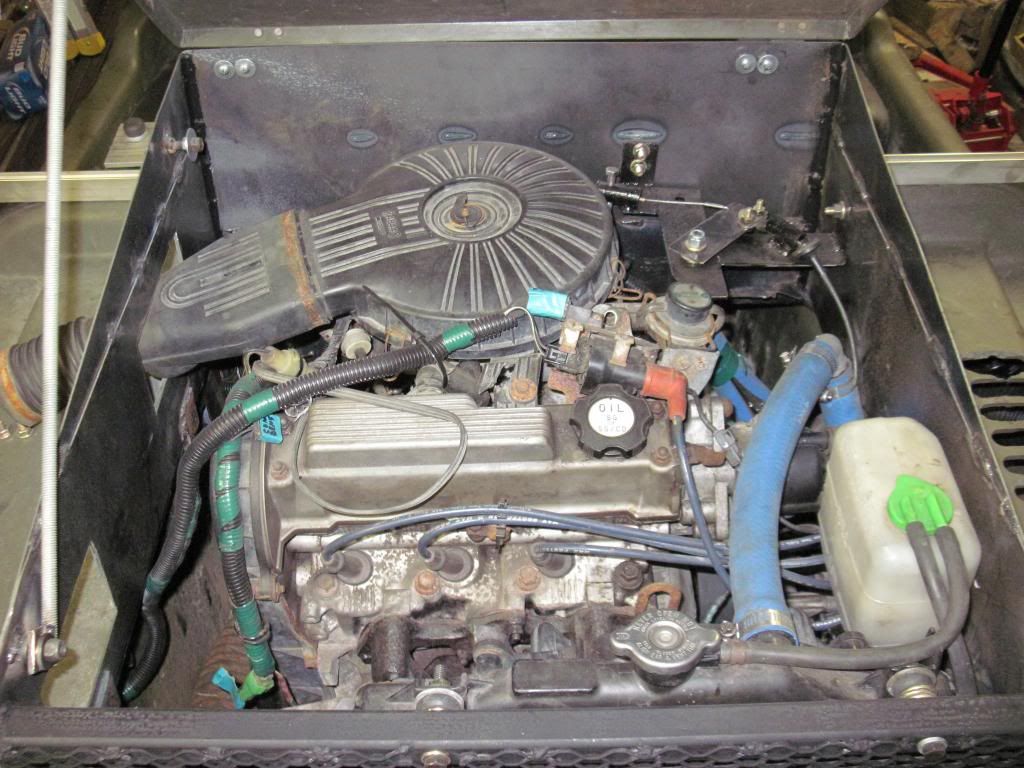

I run a snowmobile P85, 12'' center, 35mm offset, with a dayco HPX5013 (3211070). The radiator is mounted front of the engine bolted on the custom hood

Next Week i will test the machine on the trail

i got one by mistake.

i got one by mistake.

Leave a comment: