I have a hustler 950 with a fairly new Briggs 14hp engine and I'm wondering what I can do to squeeze out some more mph without swapping out the engine?she is slow ,maybe 8 to 12 mph and I would like 20ish if possible.

Different clutch, gears,belt or combination of all?thanks for any suggestions. :-)

Different clutch, gears,belt or combination of all?thanks for any suggestions. :-)

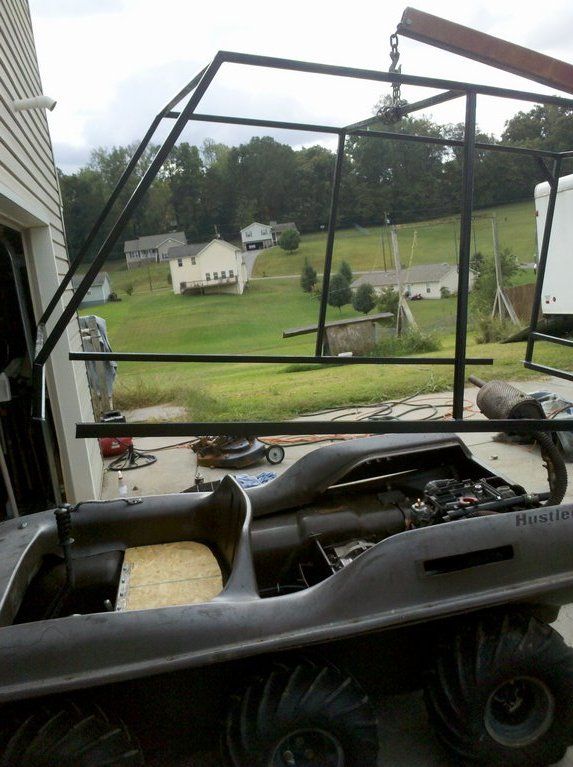

OK I can easily push the drive belt down 4 maybe 5 inches with 1 finger,heck I can wrap my hand around the top and bottom of the belt to almost touching each other.the belt seems to have lot of slack.I'll post up a picture in a few min.OK heres a few pictures.

OK I can easily push the drive belt down 4 maybe 5 inches with 1 finger,heck I can wrap my hand around the top and bottom of the belt to almost touching each other.the belt seems to have lot of slack.I'll post up a picture in a few min.OK heres a few pictures.

Yeah Byrd, you need a different, shorter belt. It *almost* looks like the belt is too narrow, too. That could also be excessive wear, too. You'll want a 1-3/16" wide belt for those clutches. If the belt number isn't visible on the outside of the belt, can you use a fabric tape measure (or piece of string) to accurately measure the belt you have now? Measure the outer circumference of the belt....

Yeah Byrd, you need a different, shorter belt. It *almost* looks like the belt is too narrow, too. That could also be excessive wear, too. You'll want a 1-3/16" wide belt for those clutches. If the belt number isn't visible on the outside of the belt, can you use a fabric tape measure (or piece of string) to accurately measure the belt you have now? Measure the outer circumference of the belt....

Comment