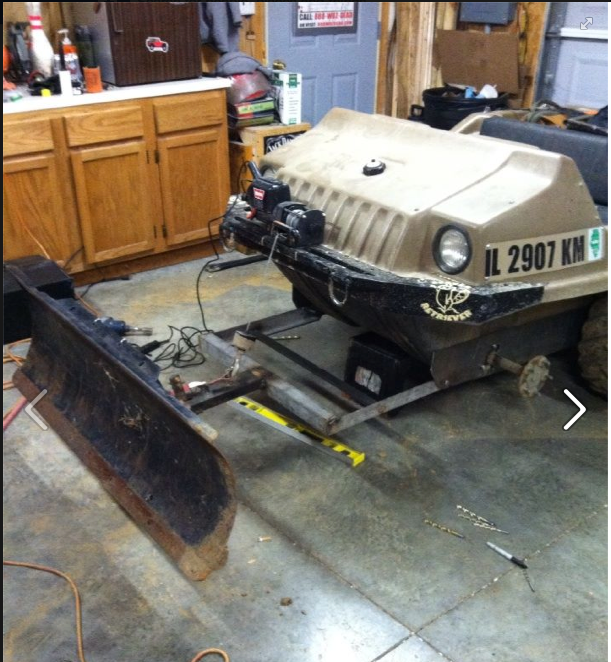

Hey all, been quite a while since Ive been on here due to work getting in the way! wanted to show you all the plow I made for my Max II. It sure doesnt look very appealing right now.....with how cold its been, I havent had a chance to paint it. also since this picture, I bought the correct plow springs for it from Sears. To date, Ive plowed with this 13 times, all of which, ive hit pot holes, parking curbs, pavement buckles etc....ive really been relieved to see, she just keeps goin!

I had a really good friend of mine do some metal work for me and it all has held up great! For the axle plates—I made a cardboard template for my friend and made it easy for him to fab up. they are made from 1/8 inch steel, bolting to the first and middle axles (bolted on top of the nuts holding the bearing flange in place). There wasnt a lot of thread exposed there, but was able to get about 6 turns off of them. I went ahead and used blue loc tite on them just to keep them secure. The front is just angle, welded together, and the plow is a 48 inch craftsman plow I bought from some guy on craigslist for $10. I use this to plow my parents office lot which is next door to my house. Its been giving the atv quite the work out since the lot is so long, but it can handle up to about 5 inches of snow. Anymore than that and I have to lower the blade half way, make a pass, then go back and get the rest. In my drive way, it can handle whatever I throw at it, no problem. but the office lot is a good 300 ft deep so the snow really loads up by the end.

Side note: if you notice, I have a non roller fairlead on the winch. Rookie mistake on my part. It was one of those "eh i'll order one" then forget. As im typing this, Im waiting on the UPS man to show up with a roller fairlead and new winch cable. Both the original fair lead and cable are destroyed from repetitive use. Im not worried about it, but for those who are looking to do this, make sure your winch is properly set up.

I had a really good friend of mine do some metal work for me and it all has held up great! For the axle plates—I made a cardboard template for my friend and made it easy for him to fab up. they are made from 1/8 inch steel, bolting to the first and middle axles (bolted on top of the nuts holding the bearing flange in place). There wasnt a lot of thread exposed there, but was able to get about 6 turns off of them. I went ahead and used blue loc tite on them just to keep them secure. The front is just angle, welded together, and the plow is a 48 inch craftsman plow I bought from some guy on craigslist for $10. I use this to plow my parents office lot which is next door to my house. Its been giving the atv quite the work out since the lot is so long, but it can handle up to about 5 inches of snow. Anymore than that and I have to lower the blade half way, make a pass, then go back and get the rest. In my drive way, it can handle whatever I throw at it, no problem. but the office lot is a good 300 ft deep so the snow really loads up by the end.

Side note: if you notice, I have a non roller fairlead on the winch. Rookie mistake on my part. It was one of those "eh i'll order one" then forget. As im typing this, Im waiting on the UPS man to show up with a roller fairlead and new winch cable. Both the original fair lead and cable are destroyed from repetitive use. Im not worried about it, but for those who are looking to do this, make sure your winch is properly set up.

MUSCA TUR BOTA then eh?

MUSCA TUR BOTA then eh?

Comment