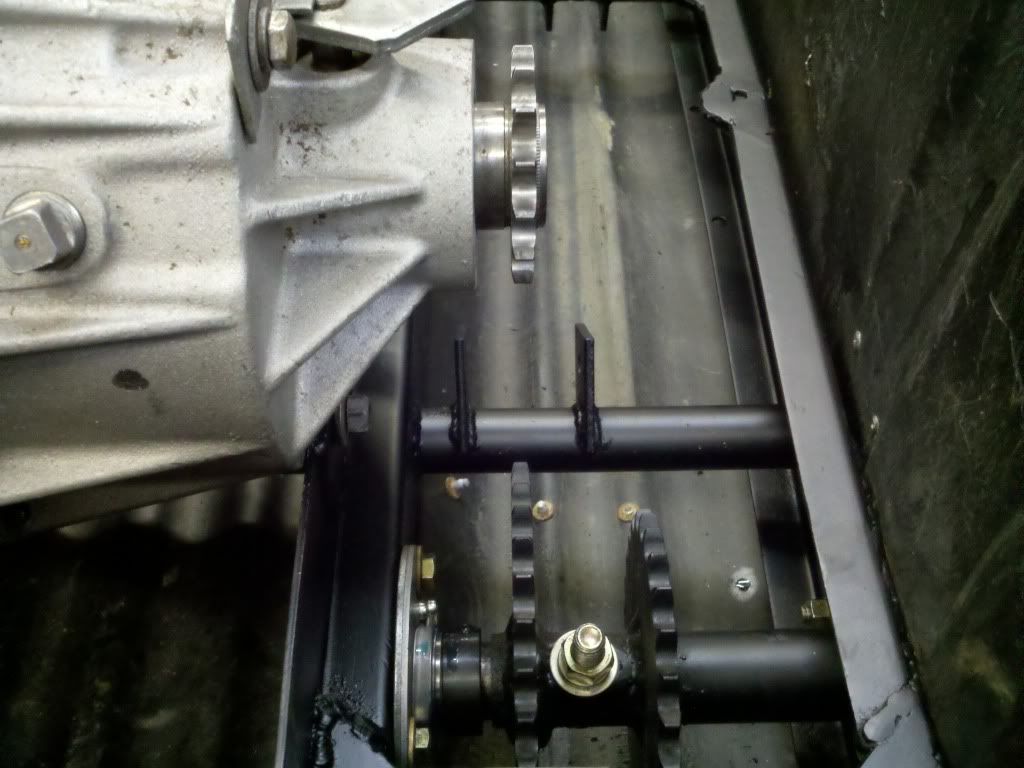

well its been a while, but Im about to slap all new bearings and chain on this maxiv. I took it down to the frame and will be welding gussets and some plate on tommorrow. I have a couple issues yet.. on the bearing flanges there is a rubber gasket between the flange and body. can I rough it up and use some Lexel or other real good silicone here? My rubber gaskets are shot. I also noticed that the inner bearing flanges have no zerk? I guess Ill add one tommorrow to them. Then I got to the rear of the frame. It looks like someone bent this thing all up with a torch to get the rear chains/sprocket to clear!?! is this factory??? good thing I got a mig and a plasma cutter! time to hammer down. any suggestions or mods I should be looking at doing while im down to the frame?

oh btw, the gears on the t20 look a little worn.. is it difficult to change them to new? or do you have to tear the t20 apart?

oh btw, the gears on the t20 look a little worn.. is it difficult to change them to new? or do you have to tear the t20 apart?

Comment