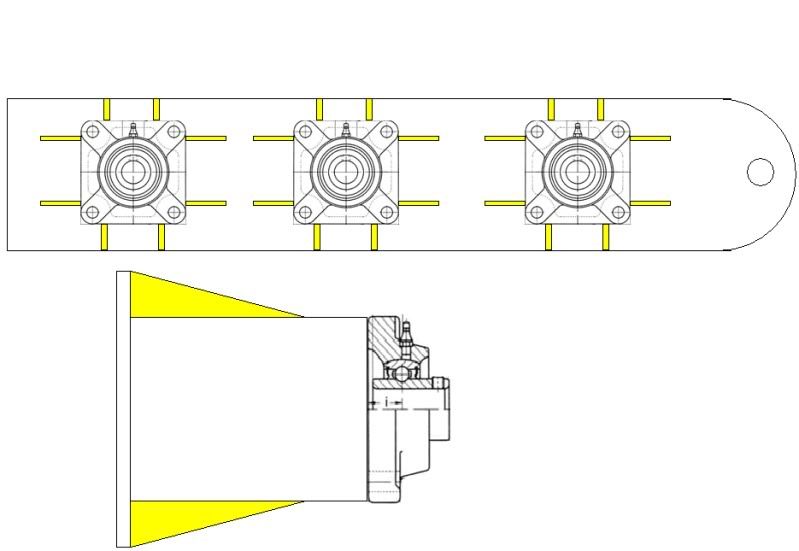

So I would like to eliminate the bushing and put in a 2 bolt flange bearing like the newer style machines. My question is can I use my hollow axles or do I have to buy newer axles as I plan on buying some solid stock steel tubing to press it into my current axles to strengthen them( I really can't afford to buy new axles right now). Any input on this subject would be appreciated.

Comment