Hi everyone, I have a problem I need some advice on. I was out this weekend testing out a new to me Max with the 25 HP Kohler magnum motor when I experienced a pretty nasty failure a few km back into the woods. I was cruising along when I bounced over a small log in the trail and all hell broke loose. I heard some crunchy grindy sounds and the motor came to a stop. After diagnosing the engine in the bush I determined I dropped a magnet (or two) from under the flywheel, this has taken out most of the stator too I assume. I found broken pieces of stator magnet around the flywheel and starter motor after removing the fan cover.

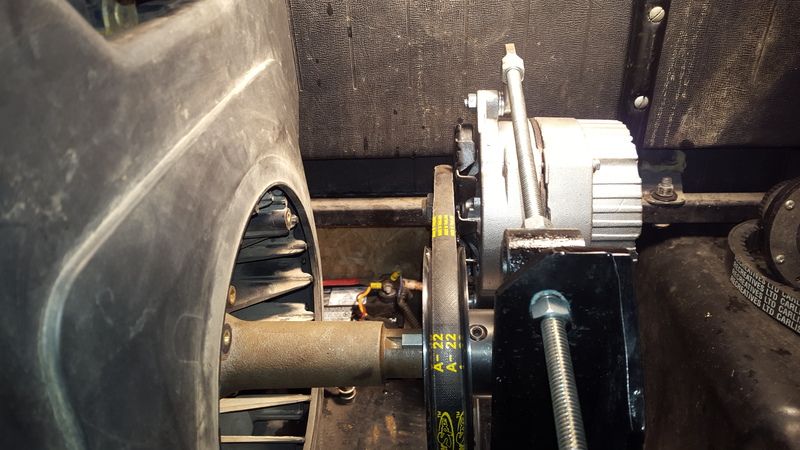

So, my question is in regards to flywheel balance. Would I be safe to remove the remaining weights from inside the flywheel? Are they spaced out evenly or do I need to worry about balance with the weight of the magnets missing? I plan of pulling the flywheel from the motor and removing all the factory charging system components from inside there and I will just run a 1 wire alternator setup but I'm not sure if I should start shopping for a new flywheel or not.

Thanks in advance for any help on the matter.

-Steve

So, my question is in regards to flywheel balance. Would I be safe to remove the remaining weights from inside the flywheel? Are they spaced out evenly or do I need to worry about balance with the weight of the magnets missing? I plan of pulling the flywheel from the motor and removing all the factory charging system components from inside there and I will just run a 1 wire alternator setup but I'm not sure if I should start shopping for a new flywheel or not.

Thanks in advance for any help on the matter.

-Steve

Comment