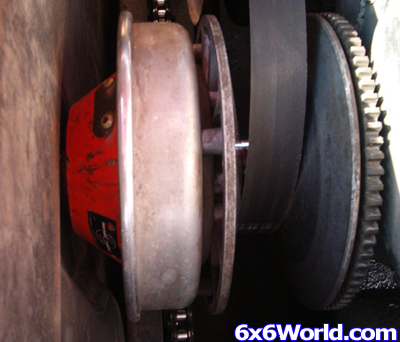

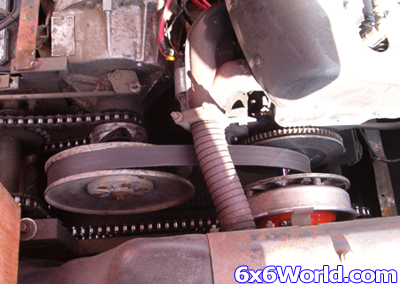

Any BRP/Rotax guys here that know how to get the orange bell housing off the 503 (maybe it's identical to other Rotax models). I finally found a puller but, It looks like I need to get the housing off before using it.

Thanks,

Mike S.D.

Thanks,

Mike S.D.

might be a cure,,,,and inexpensive too

might be a cure,,,,and inexpensive too

Comment