I just got a call and my bands are relined and on their way back to me. They told me that they had to take the plungers off to reline them. My question is how do I reattach them? Can I mig weld them?

Announcement

Collapse

No announcement yet.

T-20 Bands

Collapse

X

-

No kidding, I should have known that! I just got kind of freaked out because they charged me $5.00 a piece to remove the plungers from the bands. FYI, if you send bands to Transmission Crafters to have them relined, remove the plungers before you send them. Thanks"Racing is life. Anything that happens before or after is just waiting."

Comment

-

For as little as they charge to reline the bands, I just don't see it being worth the risk of having the material come back off. If it did come off, you are going to be out on a ride and have to get the machine home, pull the transmission again, reline the band and most likely replace a drum from the damage you caused. Replacing the one drum will cost you more than it does to get all of your bands professionally relined.Originally posted by wayne80 View PostHas anyone tried finding lining and gluing it on? I have a JD log skidder with a 20000 lbs winch I used JB wield to glue the lining on. Put on a thin layer and tightened it around a 10 inch piece of culvert pipe works good.

Comment

-

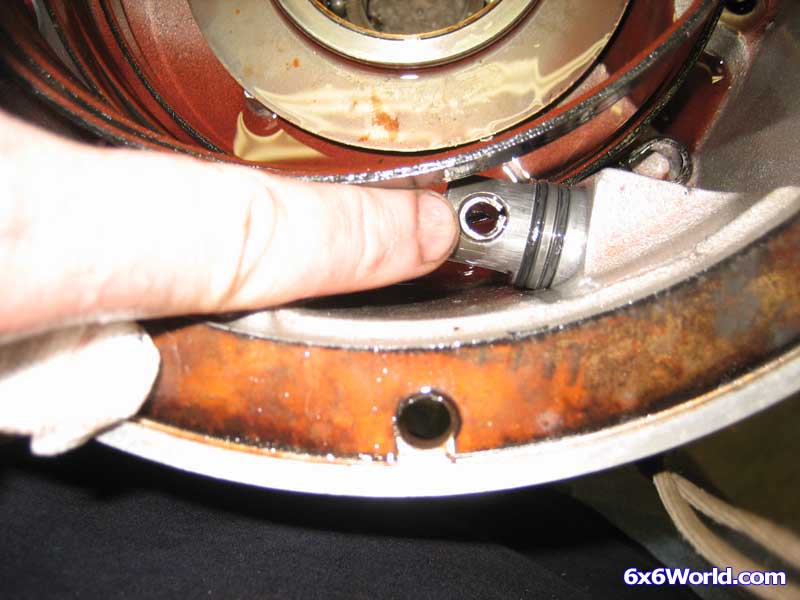

Hey Mike,Originally posted by hydromike View PostThe plungers just attach to the end of the band with a roll pin that's driven in. They're not welded. I think they're 3/8" diameter, and you can just tap them in and out.

Is this one of your stock photos or did you run to the shed, open up a tranny and snap a photo just for this thread?

Either is pretty funny. Banned

Banned

Comment

-

Just a note when reinstalling the plunger pins the split should be parallel to the plunger. If it's not the thrust can close the pin slightly allowing it to come out and ruin the case bore. Also after reinstalling try them in the case for slip fit. The ears can bend out as pin is being driven in. If you can back the plunger up on something solid to drive in the pin.

Comment

-

Thanks for the info. I will check them out when I get them.Originally posted by msafi65 View PostJust a note when reinstalling the plunger pins the split should be parallel to the plunger. If it's not the thrust can close the pin slightly allowing it to come out and ruin the case bore. Also after reinstalling try them in the case for slip fit. The ears can bend out as pin is being driven in. If you can back the plunger up on something solid to drive in the pin."Racing is life. Anything that happens before or after is just waiting."

Comment

-

Originally posted by George View PostHey Mike,

Is this one of your stock photos or did you run to the shed, open up a tranny and snap a photo just for this thread?

Either is pretty funny.

Oddly enough, I usually keep a T-20 case half in my wallet for just such an occasion.

(it's one of Admin-Mike's photos from his T-20 tear-down article... )

Thanks for the added information about the plungers Msa... I was going to add that but didn't. That's an interesting method with the roll-pins; it makes perfect sense. Have you seen many loosen up and wiggle out before?sigpic

Comment

Comment