Hello,

I changed the engine of my max II from 425ccm 16Hp Tecumseh to 993ccm 35Hp Briggs. Both 4Stroke nearly same rpm max.

both belt pulleys are from the old engine. Original springs in them.

The new engine makes 3600rpm max. Then the max goes about 45mph.

The cluch is from the 1980s. I think Salisbury 770 clutch. The engraved text says 5000rpm max, but not at wich rpm it is fully engaged! if you look at the clutch when you give throttle it is fully engaged before the engine turns ist max. rpm.

My problem:

When im driving and start accelerating the engine first revs up and then the Max starts to get faster till it reaches top speed. If i then hit lose ground (plowed field) the rpm stays the same but the clutch goes back to slower translation/Speed but the engine has still lots of power. I can hit max rpm of engine but the Max won´t reach more Speed than about 15mph due too the not fully engaged clutch on crankshaft.

My question:

would the "legendary" red spring make my performance better? Would not rev the engine so high to get fast in rough terrain. It has enough tourque but i can´t use it...

is the red spring softer?

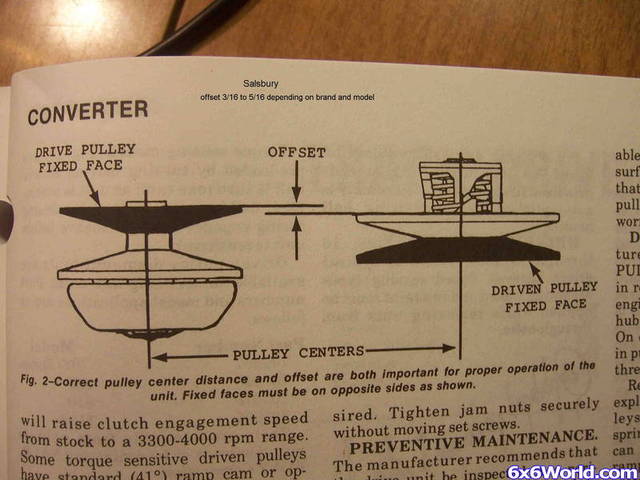

Clutches are lined up correctly and lenght of belt is also right.

Does anybody know when These old clutches are fully engaged? New clutches on new Max II are fully opened at 1700 says the Internet.

Would be very Kind if anybody can give me some tips,

Thanks, Jakob

I changed the engine of my max II from 425ccm 16Hp Tecumseh to 993ccm 35Hp Briggs. Both 4Stroke nearly same rpm max.

both belt pulleys are from the old engine. Original springs in them.

The new engine makes 3600rpm max. Then the max goes about 45mph.

The cluch is from the 1980s. I think Salisbury 770 clutch. The engraved text says 5000rpm max, but not at wich rpm it is fully engaged! if you look at the clutch when you give throttle it is fully engaged before the engine turns ist max. rpm.

My problem:

When im driving and start accelerating the engine first revs up and then the Max starts to get faster till it reaches top speed. If i then hit lose ground (plowed field) the rpm stays the same but the clutch goes back to slower translation/Speed but the engine has still lots of power. I can hit max rpm of engine but the Max won´t reach more Speed than about 15mph due too the not fully engaged clutch on crankshaft.

My question:

would the "legendary" red spring make my performance better? Would not rev the engine so high to get fast in rough terrain. It has enough tourque but i can´t use it...

is the red spring softer?

Clutches are lined up correctly and lenght of belt is also right.

Does anybody know when These old clutches are fully engaged? New clutches on new Max II are fully opened at 1700 says the Internet.

Would be very Kind if anybody can give me some tips,

Thanks, Jakob

), I doubt you'd gain a lot with a red spring whether or not your drive clutch is working correctly. I run the red spring on two heavier machines (the Swamp Fox and a 980 Hustler) because they're heavy and use 26" tires.

), I doubt you'd gain a lot with a red spring whether or not your drive clutch is working correctly. I run the red spring on two heavier machines (the Swamp Fox and a 980 Hustler) because they're heavy and use 26" tires.  . Most time driving on hard gravel and loose soil.

. Most time driving on hard gravel and loose soil.

Comment