I've already introduced my 86 conquest and my plans to use it in GSAR: http://www.6x6world.com/forums/argo-...tml#post217610

Here's a recent pic of it with the LED headlights and the trailer I'm in the middle of building for it:

img_6399.jpg

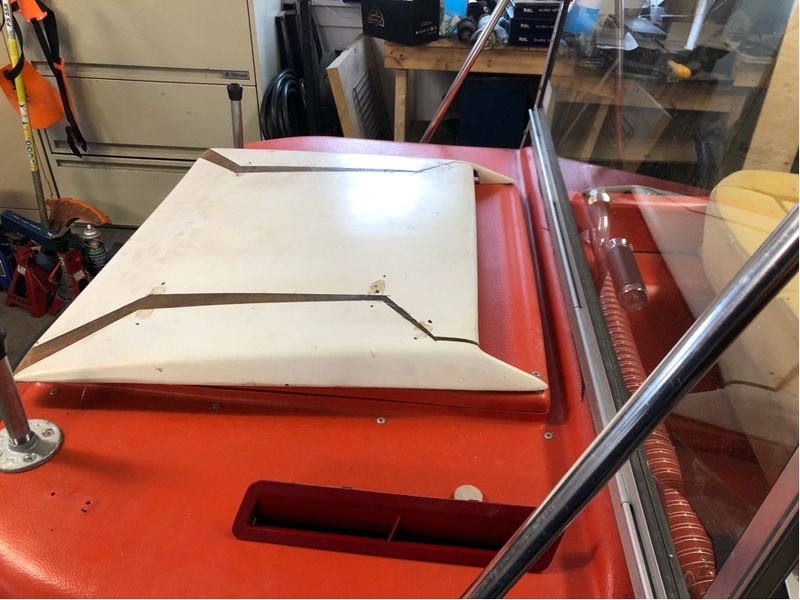

img_6679.jpg

Trailer is a converted pop up trailer. upgraded the axle, upgraded the springs, built a dovetail and built a bi-fold spring assisted gate/ramp.

I've been bouncing plans around for the old Argo and it's blown up into a full tear down project.

I toyed with names for it, SARgo being a front runner. I had thought "spider" might be cool, as it's an 8x8 and I'm going with a full suspension conversion on it. Eight articulating wheels and A-arms just seemed kinda "spidery".

But recent plans have lead me to a new name for it: Argoceptor.

(IntArgo or HondArgo just sounds stupid!LOL!)

Allow me to explain.

It's got a Kohler Magnum 18Hp in it. Runs fine, always starts cold, fairly "torquey" and has been reliable so far this year (I've only had it since summer). But there is no denying that it's just plain old and tired. And boy o' howdy is it loud! Transmission gear whine aside, that little air cooled lawn tractor engine is a rattler. It's also pretty hard to get the rig to pivot from a stop. Lots of throttle required to turn it from stopped. Part of that is the crappy knobby tires on it, but you have to get the rpms up pretty high before it will even budge at all. Almost full throttle to get it to pivot on even loose gravel. you can almost forget about it when the tracks are on. If you're not moving, you're not turning....

I've got it tuned up to where it's about as good as it's going to be and the clutches are working as per. The belt is also fairly new. So it's just the kohler and old age that's the problem. No shame in it, 31 years of service more than anyone would expect of such a basic engine. I'm thinking it's time to retire it, probably re-purposed in some other type of yard equipment like a snow blower attachment or a lawn rake/vacuum. It still runs, so I'll find a purpose for it.

Thinking about a replacement engine now, I checked around to see whats available. Lots of Briggs options and the various car engines (sprint, etc). A wrecked quad or side by side would be another option. All of them are not without a somewhat considerable cost and some requiring a fair bit of fabrication.

Well, I'm cheap and we're in the middle of building a new house. So that kind of knocks out an "off-the-shelf" engine option.

Fabrication is nothing new to me, so I figured i'd look at swaps.

Sprint/firefly/swift swaps seem to have been done with varied degrees of success. Fuel injection and whatnot would be nice. But I'd have to find a car, buy it and have the carcass around until I had salvaged everything I needed/wanted out of it. Assuming you can find one around these parts with a decent engine, you're looking at anywhere from 1000-2000 bucks. Scrap yards won't even sell you the whole car, which means buying parts and that is going to drive the cost up to around what you would pay for a whole used car. The wife is not going to buy off on a stripped car hanging around the new house, and I'm not enthusiastic about that either. No, that's out.

But, tucked away back in the shed is my 1985 Honda V45 Interceptor:

img_1332.jpg

It's a project that stalled a long time ago. It's been sitting for about 10 years (engine properly stored). It's a low mileage (35K KMs) 750 cc engine. HP is right around 80-90, torque is at the 46 ft/lb mark at 7500rpm. That torque looks to be at high rpm for a crawler like and Argo, but being a 180 degree crank and a 90 degree V4, the torque curve is almost flat right off idle. At 1500 it's making as much as the Kohler is rated, at 2,000 rpm the Kohler doesn't stand a chance.

I'm not hurting for bikes (83 Yamaha Venture and 89 FJ1200), so the Interceptor is going to donate it's engine and electrics.

Hence; Argoceptor

Fitting it to the frame isn't a problem, that's just working out the mounts and alignment. Coincidentally, the V45 is pretty much right about the same size as the Kohler withing a few inches here and there. Weight is also close, somewhere around 30-40 lbs more (mostly because of the integrated transmission). Liquid cooled means it's much quieter than the Kohler and opens up the option of a cabin heater arrangement for winter.

I'm also toying with just dumping the Argo frame all together and building something like this:

argoframe17.jpg

I can feel the current frame twisting and bending over terrain like a warm twizzler, so making a new one makes sense to me to form a solid base for a suspension and the V45 engine.

The V45 has an integrated transmission, so I have to figure out what to do for shifting it. The output shaft on the V45 will just use a regular style drive chain to the Argo transmission. I'll machine out a sprocket to fit the input shaft on the Argo transmission to accept the drive chain. Current plans are to run it open, but I may go to an oil bath like this gents made for a Razor conversion:

oilbath.jpg.

Clutch is easy, I'll just use the interceptor hydraulic clutch and mount the master cylinder on the LH lever/bar.

High/Low/Reverse will just be the stock Argo box/shifter.

Shifting the V45 will be via a "heel-toe" pedal on the floor of the Argo.

Throttle will be the same twist grip arrangement on the RH lever, but the one off the Interceptor. Steering will be the stock Argo Hydraulic brakes.

The Interceptor electronics will be stripped of unnecessary bits and adapted to the Argo body. Likely, most o f the Argo electrics will go in the trash, except for the brake cooling fans, bilge pump, etc.

Exhaust is another question. But I've got an old V4 4-into-1 header that will chop up and MIG up nicely, allowing me to build my own exhaust. At least to the point where I can either get it outside the tub or run it to a rear exit. A rear exit would allow me to use the exhaust hole in the body as a radiator air inlet so i may go that way.

The V4 is one quiet and smooth engine. Being a 90degree V4, it has perfect primary balance, so nearly no vibration. It was designed this way do it could be solid mounted in the bike as a stressed member. But it also means I can just hard mount it in the Argo with reasonable confidence it's not going to crack anything, at least from vibration...

So that's the plan. Long term project for sure. Probably won't start until next winter some time as building, moving in and setting up the new house is going to eat up most of my time for the next year or so....

Here's a recent pic of it with the LED headlights and the trailer I'm in the middle of building for it:

img_6399.jpg

img_6679.jpg

Trailer is a converted pop up trailer. upgraded the axle, upgraded the springs, built a dovetail and built a bi-fold spring assisted gate/ramp.

I've been bouncing plans around for the old Argo and it's blown up into a full tear down project.

I toyed with names for it, SARgo being a front runner. I had thought "spider" might be cool, as it's an 8x8 and I'm going with a full suspension conversion on it. Eight articulating wheels and A-arms just seemed kinda "spidery".

But recent plans have lead me to a new name for it: Argoceptor.

(IntArgo or HondArgo just sounds stupid!LOL!)

Allow me to explain.

It's got a Kohler Magnum 18Hp in it. Runs fine, always starts cold, fairly "torquey" and has been reliable so far this year (I've only had it since summer). But there is no denying that it's just plain old and tired. And boy o' howdy is it loud! Transmission gear whine aside, that little air cooled lawn tractor engine is a rattler. It's also pretty hard to get the rig to pivot from a stop. Lots of throttle required to turn it from stopped. Part of that is the crappy knobby tires on it, but you have to get the rpms up pretty high before it will even budge at all. Almost full throttle to get it to pivot on even loose gravel. you can almost forget about it when the tracks are on. If you're not moving, you're not turning....

I've got it tuned up to where it's about as good as it's going to be and the clutches are working as per. The belt is also fairly new. So it's just the kohler and old age that's the problem. No shame in it, 31 years of service more than anyone would expect of such a basic engine. I'm thinking it's time to retire it, probably re-purposed in some other type of yard equipment like a snow blower attachment or a lawn rake/vacuum. It still runs, so I'll find a purpose for it.

Thinking about a replacement engine now, I checked around to see whats available. Lots of Briggs options and the various car engines (sprint, etc). A wrecked quad or side by side would be another option. All of them are not without a somewhat considerable cost and some requiring a fair bit of fabrication.

Well, I'm cheap and we're in the middle of building a new house. So that kind of knocks out an "off-the-shelf" engine option.

Fabrication is nothing new to me, so I figured i'd look at swaps.

Sprint/firefly/swift swaps seem to have been done with varied degrees of success. Fuel injection and whatnot would be nice. But I'd have to find a car, buy it and have the carcass around until I had salvaged everything I needed/wanted out of it. Assuming you can find one around these parts with a decent engine, you're looking at anywhere from 1000-2000 bucks. Scrap yards won't even sell you the whole car, which means buying parts and that is going to drive the cost up to around what you would pay for a whole used car. The wife is not going to buy off on a stripped car hanging around the new house, and I'm not enthusiastic about that either. No, that's out.

But, tucked away back in the shed is my 1985 Honda V45 Interceptor:

img_1332.jpg

It's a project that stalled a long time ago. It's been sitting for about 10 years (engine properly stored). It's a low mileage (35K KMs) 750 cc engine. HP is right around 80-90, torque is at the 46 ft/lb mark at 7500rpm. That torque looks to be at high rpm for a crawler like and Argo, but being a 180 degree crank and a 90 degree V4, the torque curve is almost flat right off idle. At 1500 it's making as much as the Kohler is rated, at 2,000 rpm the Kohler doesn't stand a chance.

I'm not hurting for bikes (83 Yamaha Venture and 89 FJ1200), so the Interceptor is going to donate it's engine and electrics.

Hence; Argoceptor

Fitting it to the frame isn't a problem, that's just working out the mounts and alignment. Coincidentally, the V45 is pretty much right about the same size as the Kohler withing a few inches here and there. Weight is also close, somewhere around 30-40 lbs more (mostly because of the integrated transmission). Liquid cooled means it's much quieter than the Kohler and opens up the option of a cabin heater arrangement for winter.

I'm also toying with just dumping the Argo frame all together and building something like this:

argoframe17.jpg

I can feel the current frame twisting and bending over terrain like a warm twizzler, so making a new one makes sense to me to form a solid base for a suspension and the V45 engine.

The V45 has an integrated transmission, so I have to figure out what to do for shifting it. The output shaft on the V45 will just use a regular style drive chain to the Argo transmission. I'll machine out a sprocket to fit the input shaft on the Argo transmission to accept the drive chain. Current plans are to run it open, but I may go to an oil bath like this gents made for a Razor conversion:

oilbath.jpg.

Clutch is easy, I'll just use the interceptor hydraulic clutch and mount the master cylinder on the LH lever/bar.

High/Low/Reverse will just be the stock Argo box/shifter.

Shifting the V45 will be via a "heel-toe" pedal on the floor of the Argo.

Throttle will be the same twist grip arrangement on the RH lever, but the one off the Interceptor. Steering will be the stock Argo Hydraulic brakes.

The Interceptor electronics will be stripped of unnecessary bits and adapted to the Argo body. Likely, most o f the Argo electrics will go in the trash, except for the brake cooling fans, bilge pump, etc.

Exhaust is another question. But I've got an old V4 4-into-1 header that will chop up and MIG up nicely, allowing me to build my own exhaust. At least to the point where I can either get it outside the tub or run it to a rear exit. A rear exit would allow me to use the exhaust hole in the body as a radiator air inlet so i may go that way.

The V4 is one quiet and smooth engine. Being a 90degree V4, it has perfect primary balance, so nearly no vibration. It was designed this way do it could be solid mounted in the bike as a stressed member. But it also means I can just hard mount it in the Argo with reasonable confidence it's not going to crack anything, at least from vibration...

So that's the plan. Long term project for sure. Probably won't start until next winter some time as building, moving in and setting up the new house is going to eat up most of my time for the next year or so....

Comment