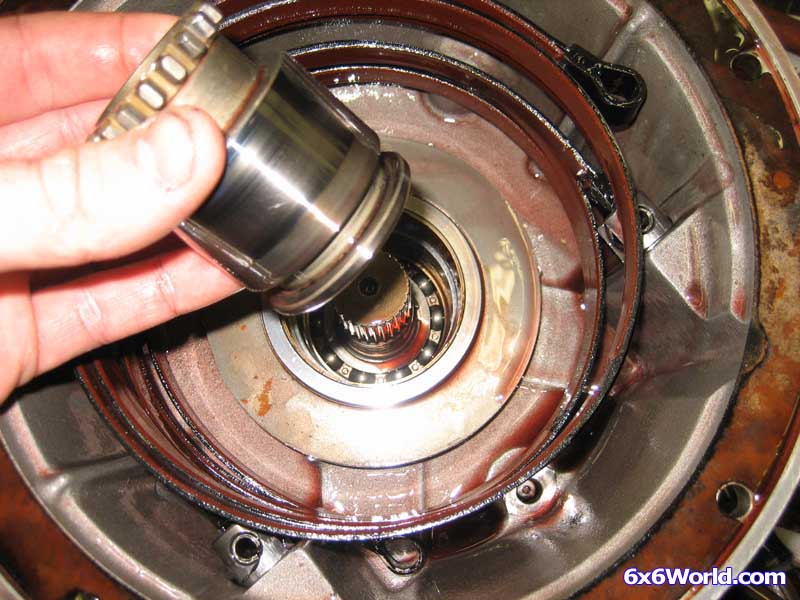

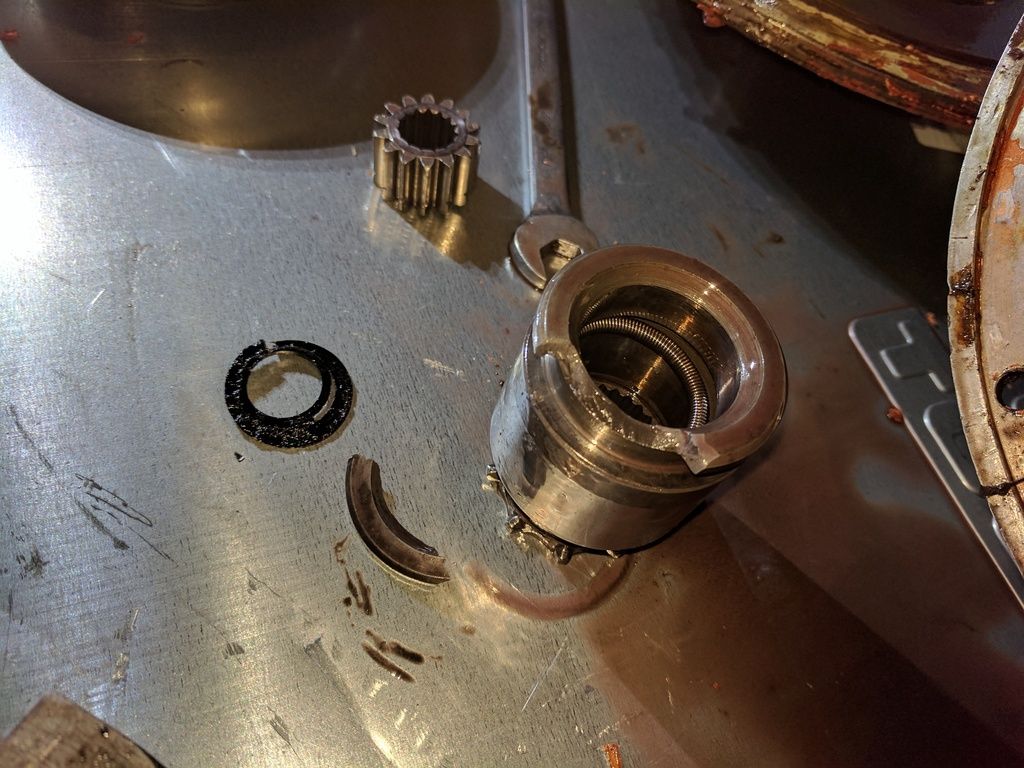

I think I have too much pre-load on the spring. Reading up on them I've read between a 1/4 and 1/3 of a turn is sufficient and I turned mine a full half. The coil spacing made me suspicious. I'm going to pop the snap ring off and go for the 1/4 to 1/3 turn.

**Edit. I think the spring may be tweaked as I dialed it down to a third and a quarter turn and it didn't look much different than in my earlier picture. I set it to a 1/3 turn pre-load and called it good.

**Edit. I think the spring may be tweaked as I dialed it down to a third and a quarter turn and it didn't look much different than in my earlier picture. I set it to a 1/3 turn pre-load and called it good.

Comment