Got a 9-tooth collar, 9-tooth carrier plate and a gasket/seal/thrust washer set in so now I have to find some time to change out the seals and get it back together.

Announcement

Collapse

No announcement yet.

TheSilverBuick MAX II Project

Collapse

X

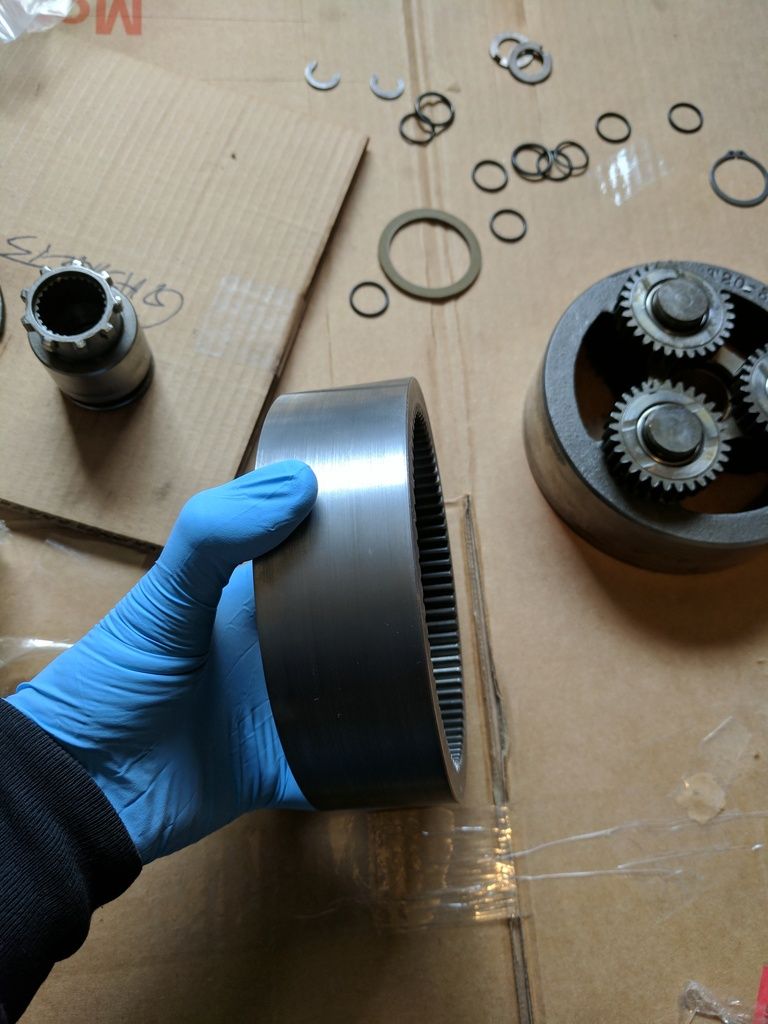

-

While cleaning it up I started to really not like the look of one of the drums (bottom right one in the picture) so thought before I attempt a re-use I'd check e-bay and as luck would have it there was two of them on there for $45. So I bought one. The other drum (top right) has slight grooves on it and I think I'll try and see if the guy at the local O'reily's (he's actually pretty good!) to make a light pass on it with their drum/rotor surfacing machine. Not sure if their setup can, but I'll ask. The other two drums just need a light polish to knock the surface rust off.

Comment

-

I've assembled half the transmission, but will be taking it back apart to put new bands in. Decided to replace the band that was all twisted up and damaged... Then looked at it some more and one of the other bands looked like it has a rough spot on it too. On E-bay Alto Products had one set of 4 bands on sale for $320, and looking at their website it was listed in their clearance section, so I threw an offer of $250 at it, and they came back with $295 and free shipping, and being e-bay tax free. Still a little more than I wanted to pay, but once I get this last drum turned (seems no auto shops have a conventional lathe anymore...), new bands, shims and seals, this T-20 will pretty much be new. And now I have a bit over $1,000 in the Max.

Comment

-

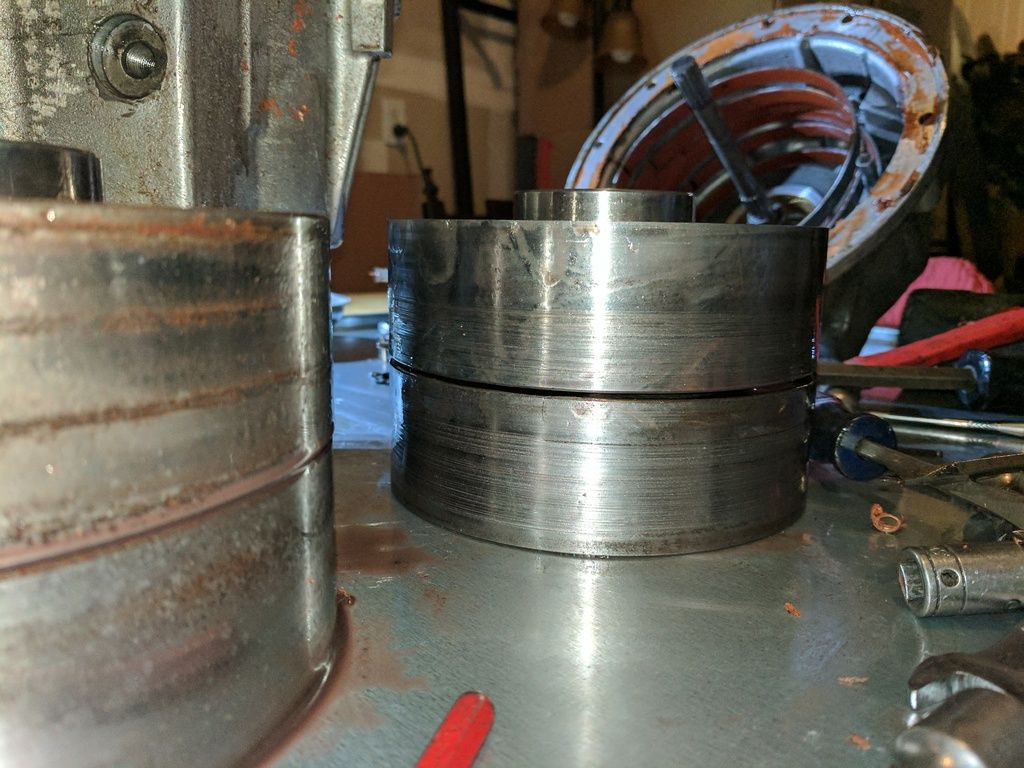

I believe the machinist said between .010" and .015". I gave him direction to cut down until the bevel on the edge is gone if necessary, but no further. If it didn't clean up by then I'd take it as cleaned up as that, but it still has some bevel left so not bad at all. I'm not sure if these are machined like car brake rotors or not, but the cheater method of telling if a brake rotor can be cut or not is the bevel on the edge, they can be cut until the bevel is gone, so I took that approach here.

Said it only took him 15 minutes and cut like butter, Easy $40, not sure why so many shops had a problem with trying it or putting it off.

Comment

-

I resurfaced a set of four drums for a forum member a few years back. Visually, they were beat up pretty bad, but only need about 0.020" taken off for a reduction in diameter of 0.040". There was an old argument that machining the drums was a bad idea because they become too small for standard bands, and the plungers are going to stick out of the case too far. Sure, they stick out a bit more but it's negligible. The drums are nice and soft and machine nicely. There's plenty of material there and it only makes sense to reuse them where possible.Originally posted by TheSilverBuick View PostSaid it only took him 15 minutes and cut like butter, Easy $40, not sure why so many shops had a problem with trying it or putting it off.sigpic

Comment

-

I got busy! Got another one of my cars to the house from across the state as well as my utility trailer that I'll use to move the MAX around.

My current issue is, I got the transmission together (thank you for the guides on the main page!) but before I put it back in I was trying out the shifting and I cannot get left side to engage forward. The shifter is simply won't go. It'll do neutral and reverse. I haven't had the time to mess with it more, either play with the bands and turning the input shaft to see if I can get the drum to rotate or a complete disassembly to see where I went wrong? I'm hoping to get it sorted out this weekend.

Comment

Comment