About 3 months ago I got a MaxII with tracks and only 5 of the adapters.

I only got it for the OH180 to replace the OH160 in my Magnatrac MT1800 Dozer.

My plan was to swap the motor's and then get rid of it.

Luck would have it after fixing the wheels and replacing one missing Chane I took it for a short drive and fell in love with it, Now I will leave it alone and repair it to full operation.

The best part is I got it all for $150.

Now the repairs begin starting with the Exhaust. the flex pipe keeps braking and i don't want to buy 25 feet of it. I found that 1" flexible gas piping for natural gas or LP seems to work rely well and is more flexible than the standard flex pipe.

This is the new piping.

I just need to finish welding it up with the Tig welder.

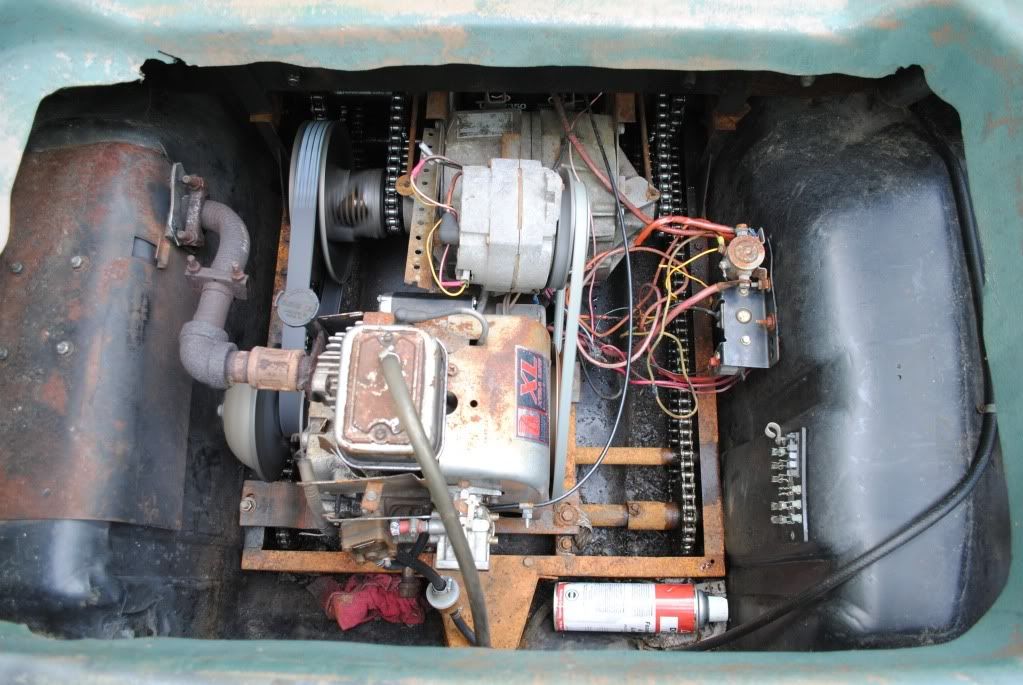

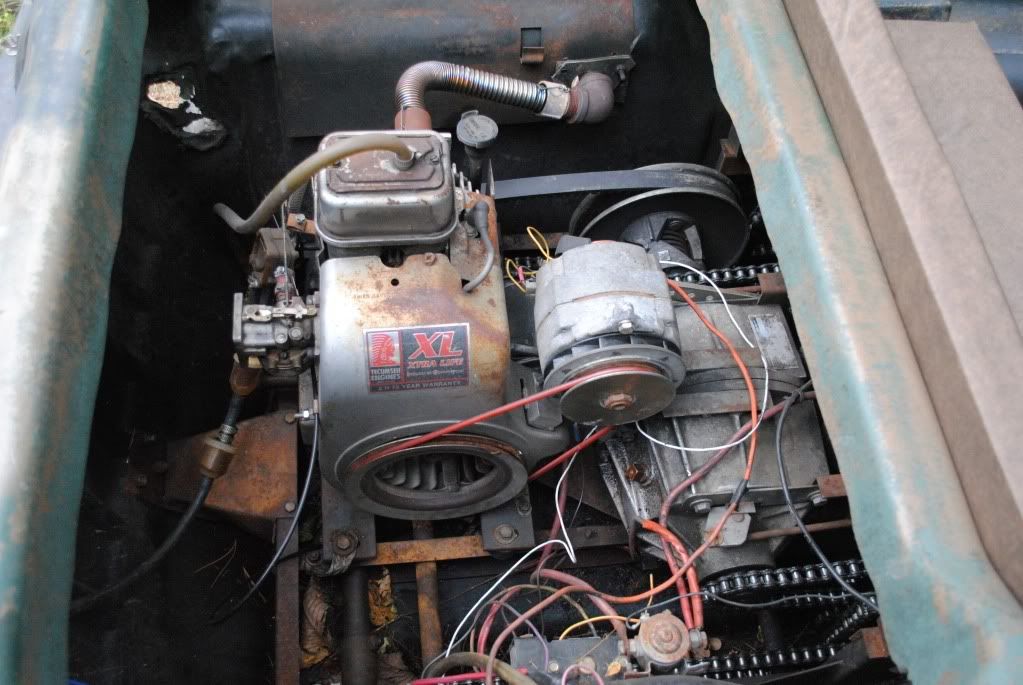

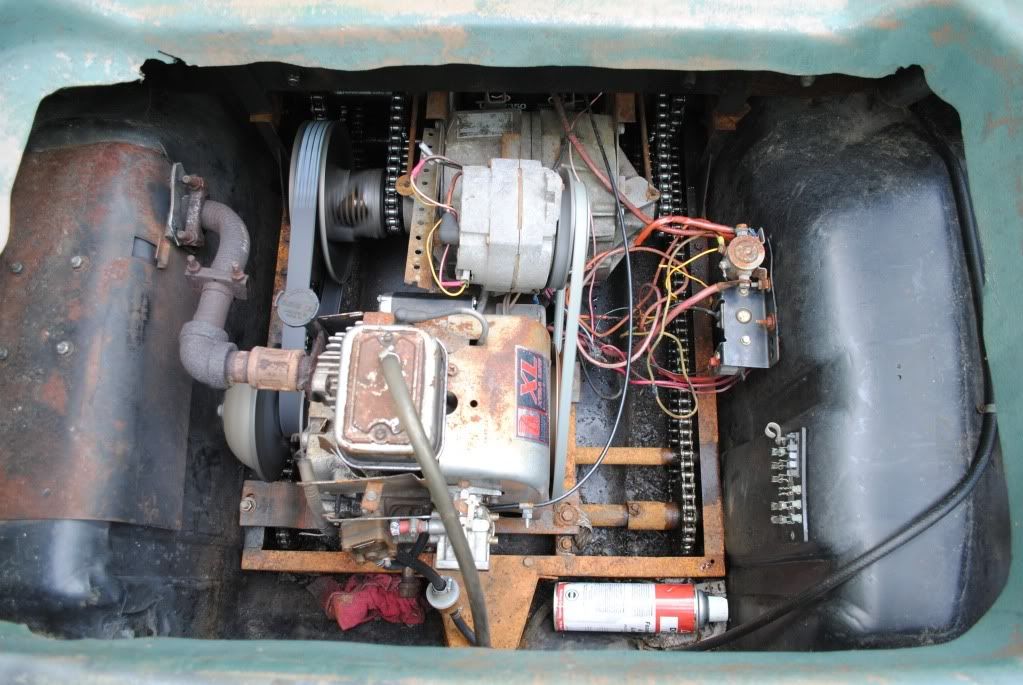

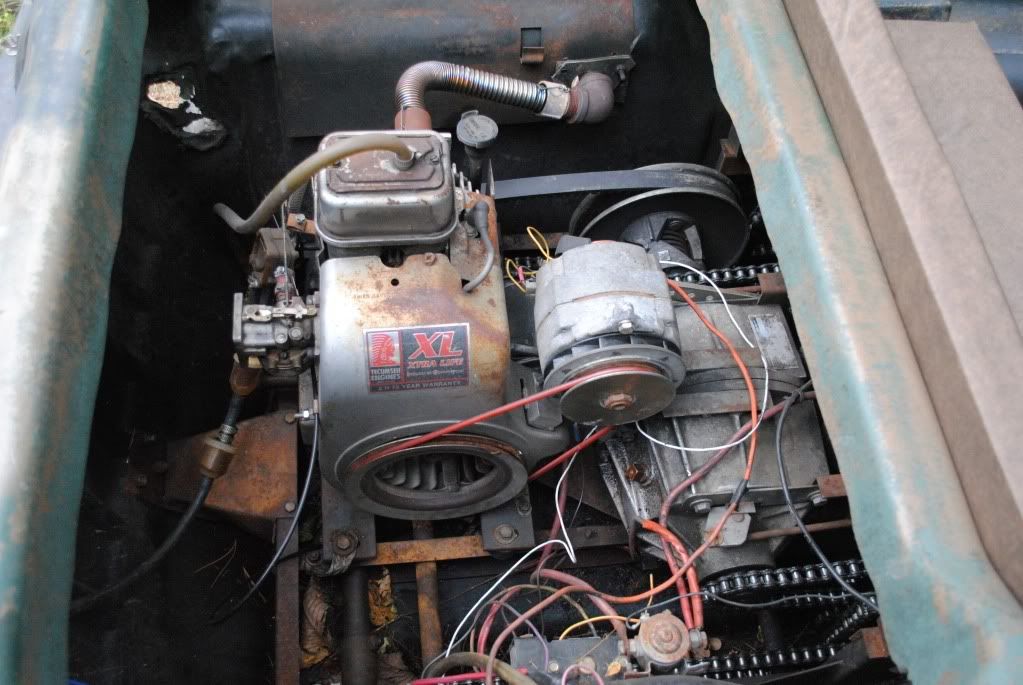

The next thing i fixed was the alternator that sum-won installed do to a faulty regulator on the original charging system.

There was no-way to adjust the belt tension do to thay made the alternator un-adjustable. the belt don't fit the manual starter pulley ether and when the motor moves it jumps off.

The new Belt I made up with industrial poly belting works real good and the best part is it's like a big rubber band and stretches when the motor moves and it fits in the motor starter pulley with room to still use the rope.

I still need to fix up the wiring.

Wen i got the machine it did not have a seat, after looking around at different options I went and made my own.

When i built the seat I also replaced the cable for the throttle with one I got off Ebay.

It's still a work in progress but fun to drive, I just need to find a place to really try it out.

You can see more of it hearMaxII 6X6 pictures by kb2rww - Photobucket

I only got it for the OH180 to replace the OH160 in my Magnatrac MT1800 Dozer.

My plan was to swap the motor's and then get rid of it.

Luck would have it after fixing the wheels and replacing one missing Chane I took it for a short drive and fell in love with it, Now I will leave it alone and repair it to full operation.

The best part is I got it all for $150.

Now the repairs begin starting with the Exhaust. the flex pipe keeps braking and i don't want to buy 25 feet of it. I found that 1" flexible gas piping for natural gas or LP seems to work rely well and is more flexible than the standard flex pipe.

This is the new piping.

I just need to finish welding it up with the Tig welder.

The next thing i fixed was the alternator that sum-won installed do to a faulty regulator on the original charging system.

There was no-way to adjust the belt tension do to thay made the alternator un-adjustable. the belt don't fit the manual starter pulley ether and when the motor moves it jumps off.

The new Belt I made up with industrial poly belting works real good and the best part is it's like a big rubber band and stretches when the motor moves and it fits in the motor starter pulley with room to still use the rope.

I still need to fix up the wiring.

Wen i got the machine it did not have a seat, after looking around at different options I went and made my own.

When i built the seat I also replaced the cable for the throttle with one I got off Ebay.

It's still a work in progress but fun to drive, I just need to find a place to really try it out.

You can see more of it hearMaxII 6X6 pictures by kb2rww - Photobucket

[/IMG]

[/IMG]

Soo, what bender do you have?

Soo, what bender do you have?

Comment