Well hello to all. My name is Russ. Just to give ya a little background about myself. I am 22 years old, live in Baltimore, MD. I work for Alban Tractor Co, which is a Caterpillar Equipment dealership. I love to hunt. I primarily hunt on the eastern shore of maryland. I hunt small elk like deer called sika deer. They roam the low lying swamps of the shore. This is were i plan to take my 6x6 once i'm done with it. So to the good stuff.

I am the proud owner of this up and coming 89 max ii 6x6. Bought it about 1 month ago and have done some pretty good work to it so far. I figured on making this thread to document my process and just show off work as well as get some help from forum members who are willing to give me some advice. So heres the story.

89 Max II. Pretty rough shape when i bought it. Craigslist ad said doesn't run, sat for year, axle bearing out. So i thought ok, not to bad. To my dismay when i arrived, it had two axles out, hadn't been moved in prolly over 4 years, prolly hasnt ran in 6 or more, sprokets lodged underneath frame against lower body, pretty rough, dirty, and rusted shape. Pretty much to say the guys asking price of $1000 was way over what this thing was worth. Well, money talked and no bull**** on my side and i picked it up for a very lower price. Anyways, i brought it home and started dissassembling.

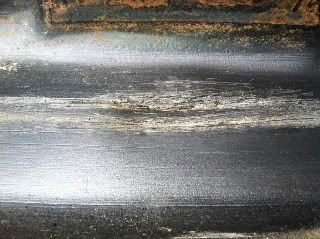

First couple days- pulled off upper body. Found gas tank full of rust, dirt, and water and old gas. Throttle cable broken and froze up. Engine full of leaves and twigs inside of flywheel. (Mouse was living in there lol). Frame was pretty rusted in one spot from water sitting inside for about 5 years lol. Chains rusted together, muffler rusted bad. But from what it seems the transmission has oil and seems to be working correctly. So i fully dissassembled the entire machine. removed engine, all wiring, transmission, all sprokets, axles, wheels, tires, flanges, frame, and axle shafts through frame. From here i did an inspection and listed what i was going to need and fix. So off to my shop to clean parts.

Next couple weeks- Took axles and blasted off and coated in por-15. For those who dont know what por-15 is, it is about the best rust converter and preventer i have ever found. Once that stuff dries it has as hard as steel. Well almost. You can hit it with a hammer and it wont chip. Sand blaster all sprockets and coated in por-16. Wire wheeled complete frame and coated in por-15. Cleaned up axle shaft supports on ends with are stationary through frame. Blasted and por-15ed some other parts as well. Looked at tub and found crack in bottom were sprocket lodged under frame and created hole in tub. As well as found some cracks in tub around where muffler bolted. Cleaned inside of tub. Scrubbed and scrubbed.

Parts ordered so far. Axle bearings, axle flanges, new chain adjusters, all new chains, plastic welding rods, body wing nuts, throttle cable, throttle, t-20 trans seal kit.

So far i've taken the t-20 apart. No damage, and looked suprisingly good inside. Resealed entire trans. Forgot to take pictures of this part, but at same time my hands were a little oiled up and dirty to take pictures, but i did reseal it well.

Plans for this weekend of the 3-31, 4-1. Clean rest of tub and plastic weld it together. I will take pictures of this step to help others. I will hopefully set frame in tub. Attach trans sprokets, install trans. As for an engine. I'm hoping to pick up a small 11hp from a guy at work for a good price and hoping it will do the job for awhile until i can save for a 18+ hp motor. Anyways, ill keep updating with pictures and progess to track it myself as well as help for others possibly. As well as if i can get any hints or tips from fellow members. Thanks in advance.

I am the proud owner of this up and coming 89 max ii 6x6. Bought it about 1 month ago and have done some pretty good work to it so far. I figured on making this thread to document my process and just show off work as well as get some help from forum members who are willing to give me some advice. So heres the story.

89 Max II. Pretty rough shape when i bought it. Craigslist ad said doesn't run, sat for year, axle bearing out. So i thought ok, not to bad. To my dismay when i arrived, it had two axles out, hadn't been moved in prolly over 4 years, prolly hasnt ran in 6 or more, sprokets lodged underneath frame against lower body, pretty rough, dirty, and rusted shape. Pretty much to say the guys asking price of $1000 was way over what this thing was worth. Well, money talked and no bull**** on my side and i picked it up for a very lower price. Anyways, i brought it home and started dissassembling.

First couple days- pulled off upper body. Found gas tank full of rust, dirt, and water and old gas. Throttle cable broken and froze up. Engine full of leaves and twigs inside of flywheel. (Mouse was living in there lol). Frame was pretty rusted in one spot from water sitting inside for about 5 years lol. Chains rusted together, muffler rusted bad. But from what it seems the transmission has oil and seems to be working correctly. So i fully dissassembled the entire machine. removed engine, all wiring, transmission, all sprokets, axles, wheels, tires, flanges, frame, and axle shafts through frame. From here i did an inspection and listed what i was going to need and fix. So off to my shop to clean parts.

Next couple weeks- Took axles and blasted off and coated in por-15. For those who dont know what por-15 is, it is about the best rust converter and preventer i have ever found. Once that stuff dries it has as hard as steel. Well almost. You can hit it with a hammer and it wont chip. Sand blaster all sprockets and coated in por-16. Wire wheeled complete frame and coated in por-15. Cleaned up axle shaft supports on ends with are stationary through frame. Blasted and por-15ed some other parts as well. Looked at tub and found crack in bottom were sprocket lodged under frame and created hole in tub. As well as found some cracks in tub around where muffler bolted. Cleaned inside of tub. Scrubbed and scrubbed.

Parts ordered so far. Axle bearings, axle flanges, new chain adjusters, all new chains, plastic welding rods, body wing nuts, throttle cable, throttle, t-20 trans seal kit.

So far i've taken the t-20 apart. No damage, and looked suprisingly good inside. Resealed entire trans. Forgot to take pictures of this part, but at same time my hands were a little oiled up and dirty to take pictures, but i did reseal it well.

Plans for this weekend of the 3-31, 4-1. Clean rest of tub and plastic weld it together. I will take pictures of this step to help others. I will hopefully set frame in tub. Attach trans sprokets, install trans. As for an engine. I'm hoping to pick up a small 11hp from a guy at work for a good price and hoping it will do the job for awhile until i can save for a 18+ hp motor. Anyways, ill keep updating with pictures and progess to track it myself as well as help for others possibly. As well as if i can get any hints or tips from fellow members. Thanks in advance.

Keep us updated and keep up the excellent work!

Keep us updated and keep up the excellent work!

Comment