Originally posted by gimmegreens336

View Post

Announcement

Collapse

No announcement yet.

Kawasaki FD620D running poorly. Help?!

Collapse

X

-

Even though I'll rig up something on my machine, I would not reccommend do the same to some else's, especially when its dealling with fuel. Maybe you can look on ebay, or even www.partstree.com for the new fuel solenoid. Have you tried fixing the wire ( soldering the ends if it needs it ,,, and cleaning the solenoid and hitting it with compressed air). Im willing to bet that you can fix your current "f-s", and not spend a dime, well with the exception of some carb cleaner.HUSTLEMANIAC and a HONORARY MEMBER of the

BIGFOOT ALUMNI

-

What are you doing up at 0200 besides helping me diagnose my busted machine?? lol

I agree with you, I'm gonna reach out to someone to solder the wire back into the solenoid and test it out.

I just bought a can of sea foam, new fuel line and liquid carb cleaner. I am fixing to start some research on the rubber I'll need to replace to reassemble the carb. I'm excited to get it disassembled and cleaned up this evening.

I could potentially have her patched back together for a shake-down run this evening if I can locate the correct plugs locally. My specific engine is the FD620D-DS12. Fixing to do some research on the best plugs for this motor.

Once I get it patched back together I can start some of the things recommended.

Thanks guys! Last edited by gimmegreens336; 10-18-2012, 12:20 PM.

Last edited by gimmegreens336; 10-18-2012, 12:20 PM.

Comment

-

Yeah, about that!!!!!!! I dont sleep much when I'm on vacation.Originally posted by gimmegreens336 View PostWhat are you doing up at 0200 besides helping me diagnose my busted machine?? lol

I hope all works out ok for you and you get to make that shake down. Speaking of shake down,,,, you ever been to the "strip"??HUSTLEMANIAC and a HONORARY MEMBER of the

BIGFOOT ALUMNI

Comment

-

I don't know what the "strip" is - I mean, I've been to the "strip" at beaches and some bigger cities, just slang for where all the bars and clubs and action are I guess. What strip you referring to?Originally posted by fmints View Postyou ever been to the "strip"??

So here are a few shots from the action last night. I bought a can of liquid carb cleaner, comes with a basket you jsut drop your metal into and let it sit for approx 20 mins then rinse with water. It really cleaned the crap out of the metal parts!

A little residue at the bottom of the bowl but doesn't seem too bad.

Dirty parts

Clean parts!

This goes to Dan67 - you were right on the money with plugs. I have a FD620D motor, which would recommend a particular set of plugs generally. However, I have a specific FD620D-DS12 which calls for the BMR4A style plug, I went with the NGK brand NGK 5728. Look at the difference! The plugs that were installed when I got the machine were way too long.

This is the broken solenoid. My neighbor told me to bring it to him and he'll hook me up.

I was curious about the filter. Is a fuel filter a fuel filter? The one installed is a fine wire mesh filter, the one given to me looks like a paper filter? (The new filter is closer, the old filter is in the back) The new filter is roughly the same size, slightly smaller. Would it be ok to run the other type of filter?

My throttle cable has always stuck pretty bad, I sprayed some WD40 and it fixed it. Question is, what is best to clean all this crap off with? A degreasing chemical or soap and water or what?

I think that's it for now folks.

Thanks for keeping up! Last edited by gimmegreens336; 10-20-2012, 11:41 AM.

Last edited by gimmegreens336; 10-20-2012, 11:41 AM.

Comment

-

Strip, in my words,, meant "Dragstrip" or "Race Track"

As for the Carb Cleaner, I hope that you removed all rubber from the carb, because the concentrated cleaner will kill the rubber.

A fine wire brush, or soft wire brush, or a tooth brush will be needed to clean the black exhaust buildup inside the carb. Everything should be bright and clean when your finish. Q-tips won't hurt either just make sure that there is no cotton strings left behind. It all looks good thou buddy.

Good info on the spark plugs from Dan. After all of this, you should be rocking and rolling.

I normally use Purple Power or any degreaser with the assistance of a pressure washer, and relube everything that needs it. I run my engine while hose it all down and monitor the engine. If the engine surges or acts funny while hosing it down, then more than likely you sprayed into the carb somehow, or you have a faulty gasket somewhere. This happened to me before and I ended up replacing the intake to carb gasket, along with head gaskets. I immediately noticed a spike in my 23hp Kohler's performance.

The fuel filter should work also, so you shouldn't run into any issues there.

I also hit the inside of the throttle cable with compressed air, then WD40 or similar lubricant, and follow with more compressed air to ensure that the lubricant gets deep down inside the cable.

Hopefully, your neighbor can solder the wire back onto the fuel solenoid. With all these improvements, you should be running at 100% in no time.

Good luck, buddy, can't wait til it's all back together!!!HUSTLEMANIAC and a HONORARY MEMBER of the

BIGFOOT ALUMNI

Comment

-

I'm sorry. I just finished moving photos in the engine section of the gallery to their own album here: Carb Rebuild - Amphibious ATV Pictures but unfortunately, it destroyed the links to the photo in this thread which means you will have to relink them. If I knew which photos went where I would do that for you but I don't. Sorry for the inconvenience. It was completely my fault and I know how time-consuming this can be.

If you have more photos to share, and I hope you do even though I ruined your hard work to this point, if you will put them in the album I created in your gallery, they will be safe there. Usually if there are a lot of detailed photos I will create an album to store them in so that the main gallery isn't full of dozens of detailed shots so that's what I was doing with your photos. If I realized how many were linked here before I did that, I would have waited.

Sorry again.

Comment

-

It's all good Mike! I've got a whole new host of problems now so hopefully I'll fill the thread right back up with pics.

Fred: The "strip"! lol - No, I've not been to one. Other than the one at Busco! Good advice on testing for carb leaks. I planned on running her last night and testing until we found some throttle issues. (Explained below) I already anticipate an issue with the gasket in the middle of the carb. I bought a new one, but it's so detailed and the ledges are so thin, it seems tough to get it to seal perfectly. I ended up snipping the end of the solenoid. Neighbor said it's not repairable. He said he'd snip the end or find a bolt that fits, and a cool-down idle for about a minute before shutting down should prevent back-fire. (We'll see!) Worst case, if it diesels or back fires like crazy I will just buy a new solenoid. Man I do appreciate your help! Thanks for keeping up man!

The last run at Busco before the Conquest took her final sh**, the throttle was sticking at wide open. It happened when we put a new driver behind the sticks and it was a mess. We took the handle off at Busco to look at it, didn't notice anything out of the normal. After reassembly, it has perm cruise control. The throttle does not return to idle when you release the handle, it sticks. (But it's the handle sticking, or the throttle cable - the arms and springs by the carb are operating as normal, something is sticking somewhere else) You have to forcefully twist back to idle. I was thinking if I took the handle back off, got WD40 down into the cable, and sprayed the arms and springs in front of the carb that everything would be ok. It's not! lol

I am slacking because I should have videoed what I'm about to try and explain. First, I haven't been on a research binge yet. I will edit this post if I find my answer no the site.

So does the handle throttle control more than just the throttle valve in the carb? I ask this because there is maybe 1" of movement in the throttle shaft, moving the throttle valve from closed to open. With just a very small twist of the wrist, I can open and close the throttle valve completely. So essentially, the last 80% of my throttle twist does not move the throttle valve. If there is another function the throttle serves fine, otherwise something is funny.

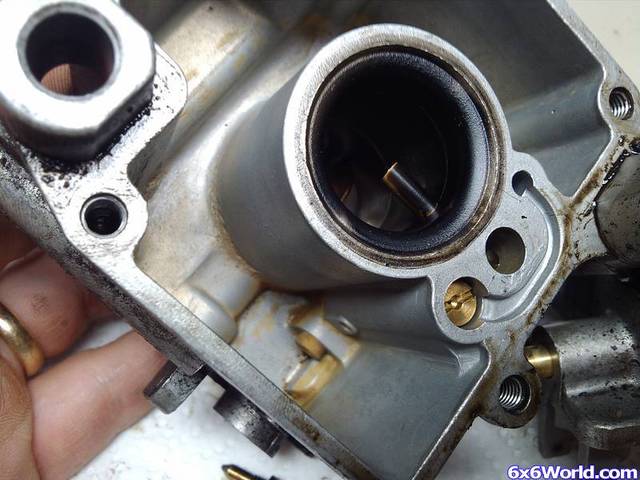

The carb is put together and installed, including the throttle and choke shafts. Everything seems correct. I don't love how "sticky" the throttle valve seems. I would love friction-less movement. The throttle valve doesn't seat at a perfect perpendicular angle to the carb bottom. When it "closes" it is slightly tilted. I guess this is normal? Just want to confirm.

Here I go on another research binge. Fred, the Argo is giving me an opportunity to learn some things for sure!

Last edited by gimmegreens336; 10-20-2012, 11:44 AM.

Last edited by gimmegreens336; 10-20-2012, 11:44 AM.

Comment

-

Hope I didn't mess up the explanation on the throttle linkage to muchOriginally posted by gimmegreens336 View PostI ended up snipping the end of the solenoid. Neighbor said it's not repairable. He said he'd snip the end or find a bolt that fits, and a cool-down idle for about a minute before shutting down should prevent back-fire. (We'll see!) Worst case, if it diesels or back fires like crazy I will just buy a new solenoid.

I won't say that snipping the end of the Anti-Backfire Solinoid is the right thing to do, but I will say that if you check any of the 5 Conquest engines I have, you will find that all of them have the Solinoid Pin Clipped off.

The last run at Busco before the Conquest took her final sh**, the throttle was sticking at wide open. It happened when we put a new driver behind the sticks and it was a mess. We took the handle off at Busco to look at it, didn't notice anything out of the normal. After reassembly, it has perm cruise control. The throttle does not return to idle when you release the handle, it sticks. (But it's the handle sticking, or the throttle cable - the arms and springs by the carb are operating as normal, something is sticking somewhere else) You have to forcefully twist back to idle. I was thinking if I took the handle back off, got WD40 down into the cable, and sprayed the arms and springs in front of the carb that everything would be ok. It's not! lol

Just a thought, If you tighten the little screws on the hand throttle assembly too tight, the throttle twist grip will not return freely.

So does the handle throttle control more than just the throttle valve in the carb? I ask this because there is maybe 1" of movement in the throttle shaft, moving the throttle valve from closed to open. With just a very small twist of the wrist, I can open and close the throttle valve completely. So essentially, the last 80% of my throttle twist does not move the throttle valve. If there is another function the throttle serves fine, otherwise something is funny.

The Throttle cable runs to a linkage on the Governer, when you pull the cable, the governor linkage moves. There is a spring that connects the governor linkage to the throttle linkage. If you are looking at it and testing while the engine is NOT running, it would appear as though there is not much happening at the throttle.

RD

Comment

-

No, that's what I was hoping for. There isn't much going on around the carb when I twist the throttle and thank goodness that's normal. I am going to remove the control panel assembly, inspect the governor arm, and do a good cleaning of all those arms/springs/levers before patching her up. I get off work in about 7 hours, hopefully have her put together tonight and begin tuning.Originally posted by Rock Doctor View PostHope I didn't mess up the explanation on the throttle linkage to much

RD

It sounds like you're telling me that clipping the end off the solenoid is, in fact, the right thing to do.

Last, I will try to loosen the screws assembling the throttle handle. I probably did tighten them thoroughly thinking the handle would slide off if I didn't tighten them. I was going to run some sand paper through the grooves that allow the handle and cable to turn, see if I can't route it out a little more.

I'm excited to get working again tonight. I really wanna get her turned over to see if my original issue is fixed.

Thanks for chiming in RD!

Comment

-

"... the right thing to do." - Now that really involves ones own personal weighing of risk -vs- reward.Originally posted by gimmegreens336 View Post... clipping the end off the solenoid is, in fact, the right thing to do. ...

The point of the thingy is to shut off the flow of fuel so it doesn't get sucked through an engine that has been shut off while there is still a good deal of inertia; only to be ignited by a still hot exhaust system. This will pop and make the unaware jump and the kids giggle.

But, there are other options. Makes the carb easier to take out if you need to rejet.

Oh, and let it idle down for a bit before you shut it off.

Comment

-

Nice, thanks JohnF for the link - was wondering about which bolt size I would need to cap it. For now, it's installed with a snipped solenoid. I gravity fed a little fuel Saturday night and fired her up. She sounds sweet, much much smoother than before. I'd attribute the success to the correct plugs more-so than the carb clean.

My biggest issue right now is the throttle cable. It's in a bind. It looks like there is a bend in the cable around the handle that's causing it to hang up. I understand I can get this cable anywhere but I was more concerned with the pieces on each end. One connects to the handle, like a small sphere that fits in the hole in the handle, the other is a flat metal with the S shaped or whatever that fits on the control panel by the carb. Maybe this is an easy fab? I'm not sure..

I also took the control panel? (the piece with springs and arms connecting the throttle cable and choke cable to the carb) apart and cleaned all the grime and lubed it real good. The springs seem loose. They may need replacement.

The "new" shiny carb.

I hardly had an opportunity to work on her yesterday, we threw (my wife's idea) a gender reveal party with friends and family. We are having a GIRL! I'm pumped and already wrapped around her finger.

Comment

-

Jeez - I did bend/rig all of them to be tight before I started the motor... maybe that's why the RPM's are high at idle when I gravity feed the fuel? I think I can un-bend them. Hopefully I'll get to work tonight on it, I will report back tomorrow.Originally posted by Rock Doctor View PostTry not to mess with the springs too much yet. The one going from the governor linkage to the throttle linkage should be loose when the engines not running.

Which others are loose?

RD

Thanks RD

Comment

-

Yes that will make your idle high. At an idle, your governor should not be trying to control your RPM.Originally posted by gimmegreens336 View PostJeez - I did bend/rig all of them to be tight before I started the motor... maybe that's why the RPM's are high at idle when I gravity feed the fuel? I think I can un-bend them. Hopefully I'll get to work tonight on it, I will report back tomorrow.

Thanks RD

When the engine is stopped, there is no tension on the Governor Linkage.

At an idle there is some tension on the governor linkage, but not enough to activate the throttle linkage

By tightening this spring, you have put a bit of tension on the throttle linkage when at an idle.

If you pull your air cleaner off, and start your engine, I bet you will see that your throttle linkage is pulled away from the little Idle Set Screw. You can probably push the throttle linkage back to where it contacts your idle set screw with your finger, and your engine will idle down. When you release it, the tension from the governor linkage will pull again and idle the engine up.

RD

Comment

-

Oh, and get a spare spring to go from the Gov to the Throttle linkage.

Now that you've bent this one, it's compromised. It might last, it might not, but I can tell you "From Personal Experience" that you DON'T want that spring to break when your sitting on a frozen lake about 16kms from the nearest road .

.

Another point,

That spring is a very specific length, if you try to bend it back to where it was, and something still doesn't seem right, there is a chance that you don't have the spring bent to the right length.

RD

Comment

Comment