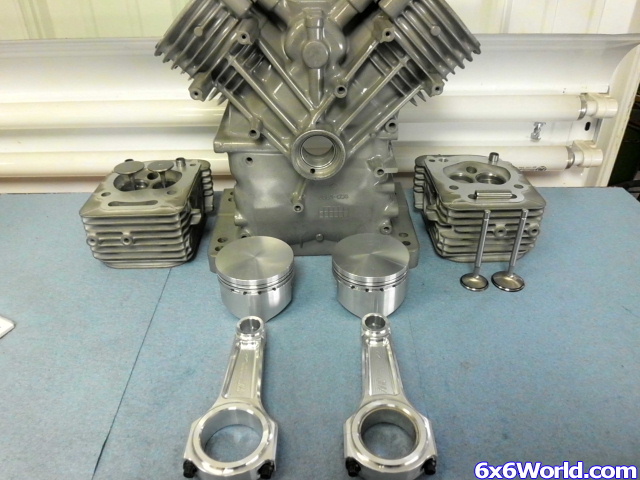

I had built some of these engines about 15yrs ago for a guy down the road that set his son up in a bandolero car. Now the son has moved on and the guy installed one in a pulling tractor for the last two seasons, now he asked me to build one with a few updates.

He wanted me to take pictures as i go so i thought i'd post them here as well

He wanted me to take pictures as i go so i thought i'd post them here as well

Comment