Originally posted by Buzz

View Post

Announcement

Collapse

No announcement yet.

A question for you track experts

Collapse

X

-

Thanks Buzz the cost is in and its doable as my machine has a ton of hours on it all chains have been purchased the original sprockets well its time anyway I already have HDI axle upgrade as of two years ago and have the axles coming out sold and have seen many snapped axles and Iam talking about the HDI style running tracks so for me its another bullet proofing its not that Iam cheap but Iam handy this Avenger has every factory option and to replace it would be 30 plus K I couldn't spend 1/3 of that to put it in top shape being retired gives you a slightly different perspective and time to do this.NCT

-

Buzz your mind travels at a heck of a rate and too fast for this Ole guy you are like receiving information from the matrix,it takes me a few reads and a bit of scratching on a pad to get anywhere near all the info you have in a couple sentences but keep it up Iam sure it will help me ward off Alzheimer,s for a while, now to the point okay so Iam going with the cast axles and lets say for now that there is no reversible rim available for the Frontier tires and I continue using the track spacers that came with my rubber tracks if possible with the new cast units where would I be on a Channel track build as far as the inner belt width is concerned and then I will attempt your calculations for what to do on the outer belt to come within reason to my current flotation levels before I attempt to dump all this information in Marcels hands.NCTOriginally posted by Buzz View PostI believe the axles are about 1.25" longer. One direction the offset in rims (also approx 1.25") is added to the increased axle length, while in the other direction the offset in rim washes out the increased axle length.

Because the 10" wide tires already have a bonus 1" of clearance on either side of the rim centerline compared to a 12" tire, a couple things come to mind. With equal spacer widths, a 10" tire can run an inner belt that is 1" wider than a 12" tire running the same style, and both have the same amount of clearance.

If you were to simply put a 1/4" spacer on each axle, or stack a couple washers on each lug stud, and you were to use the longer axles and 10" wide frontier tires, then you could run a 4" inner belt (similar to what 12" tires do with 2.5" spacers), and you would have the same amount of clearance.

Hope that makes sense. 1.25" gained from longer axles, 1" gained (towards the machine) because of the narrower 10" tire, and .25" gained from your spacer of choice. In fact, you don't really even NEED the .25" spacer part, but it would be better.

Or you use the longer axles + standard 2.5" spacer and have clearance for up to a 6" inner belt.

Comment

-

Just a fun hobby my friend, and I enjoy it! The key is sharing information from you have learned..

With the new longer axles, re-using your standard 8" diameter argo rims and 2.5" argo wheel spacers, you can run a 6" inner belt.

You do give up some footprint by going from a single 8-wheel track to a set of quad tracks on the same machine. But, it is very easy to add track width, especially with the elevated belt style track, and it remains just as easy to skid-turn. Moving to a quad track is equivalent to running a 6-wheel track on an 8-wheel machine (track widths being equal apples to apples). The tracks are moved to the corners to evenly balance the weight distribution. You simply add a bit of width to the quad tracks to get your desired footprint back.

With an elevated-belt track, added width does not make it more difficult to skid turn, it only makes the machine wider and improves performance when the conditions require it. You still drive around skid-turning a track that the machine feels as only 10" wide, in your case

A full length 18" wide rubber track = 1422 square inches VS. Quad tracks @ 27" wide = 1420 square inches (winter use for both) roughly the same

A full length 14.7" wide track = 1161 square inches VS. Quad tracks @ 22" wide (10" touching the ground and skid-turning most of the time) = 1158 square inches (summer time use for both) roughly the same

It would be very easy to run for instance a 22" elevated belt quad track and then add a 5" winter kit to get adequate deep snow floatation similar to the argo rubber track. It would be just as easy to run a slightly wider winter kit to give you an advantage. All the while, it would take 25% less torque to drive and you would get the other added benefits of the elevated belt track design. And, I believe the redundant set up you're looking for. No track tuners required for channel tracks if a quad-track set up is used.

Hope that helps, and I would strongly recommend that the inner belt edge be beveled back to just outward of the grouser-guide so that the tires do not rub. I bevel the belt back to the inner backer washers.

Hope that makes sense!

Comment

-

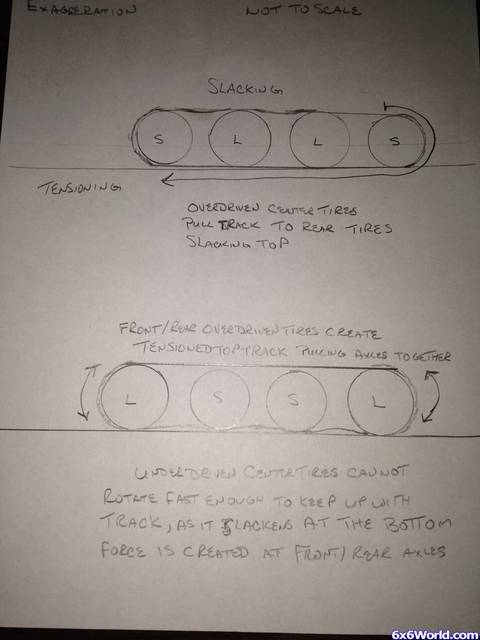

NCT, this would be a very crude visual aid as to how I see the tire indexing work, speed would be a variant as the majority of the machine weight would be carried by the 1st and 2nd axles. I would also believe that with the larger tires on the outer ends any encountered debris, such as a large rock, would become an exaggerated force as the 2nd smaller tire would take a moment to pull the track over the encountered obstacle.

Should any of you guys feel I am off kilter here please let it be known as I would not want to misdirect anyone. I am no engineer by any means.

sigpic

sigpic

My new beer holder spilled some on the trails - in it's hair and down it's throat.

Joe Camel never does that.

Advice is free, it's the application that costs.

Comment

-

I think that the side load felt by the corner axles is more related to how tight the track is. Some tracks need to be tighter than others. If the length is too short, or the corner tires are overinflated, then the corner axles see additional side load. The center tires just don't seem to affect the track tension at all in my experience. Even if the center tries are significantly overdriven, the track sagging on the top of the track is directly related to the overall length that it was built to, the sizing of the front/rear tires, and the direction of travel

Comment

-

If the track is tight, sometimes you won't even see sagging on top of the track regardless of direction of travel or the position of the tires.

Either way, even with track tuners differences in the circumfrence of the front and rear tires must be scrubbed out. The ease at which the rear tire can scrub out this difference is directly related to 1) track tension and 2) how easily the tire treads can relieve themselves of the this load due to how they interact with the track or grouser surface. Some are more forgiving than others.

Or you do your best to get the rear tire as close to the same size as the front, and then "slightly" increased the size of the rear tire to as to protect the rear tensioner.

Having a track than is compatible with being a bit loose is helpful.Last edited by Buzz; 01-01-2017, 04:19 PM.

Comment

Comment