Originally posted by Delduck

View Post

Announcement

Collapse

No announcement yet.

Tracks and phragmitis

Collapse

X

-

Gotta be honest with ya, this ones had me talking to myself lol. Been racking my brain trying to figure out how the phragmites is getting wedged like it is and that's the only conclusion I could come up with. I've done a little online research as well and every pic that had a vehicle in it was either a Marsh Master or an ARGO. Point is, you can't possibly be the only one having this problem. Hopefully my theory is correct and its shed some light on your problem....Cup

-

Delduck, in previous threads you mention the difficulty in cutting this stuff. Are you cutting it or simply running over it? I think Cup is right - driving into the top of the fallen plants is loading the tracks. Out of curiosity, did you drive the same with the Max machine? Can you run in the same direction (clockwise or counter clockwise) in your work area so that you aren't driving into the tops of the plant?

I'm thinking like Cup - that the tracks may be picking up the plant and taking it along for the ride. Your pic shows the tracks have what I will call a serrated edge, leaving plenty of opportunity for a stalk to catch. I suggest you get a person to ride along beside you and watch what is actually happening. If the tracks are picking up the material, consider bolting a 4 inch rubber belt along the inner (and outer if necessary) edge of the tracks to protect the serration and keep it from catching or biting the plant. Also, consider whether turning is shoving a bunch of material into the tracks/wheels and creating the problem. Perhaps wide, sweeping turns will lessen the issue. I know its not efficient, but neither is the cleanout time you are experiencing!

Comment

-

Johnboy may be on to something there with the split collars, blade or not, the front and rear only have 2-3 inches of axle showing so the windup there is a major problem. Guys figure a 2-3x4-5" rotating gap intertwined with weeds that find their way around the extension and then the axle again. The shaft collars, perhaps with the blade, would aid in keeping the weed just around the extension which would be much easier to clear.

Ideally a leading flail or brush mower would do great but both are probably to heavy for the terrain and machine.

I believe Bob said all his issues are on the initial knock down.sigpic

My new beer holder spilled some on the trails - in it's hair and down it's throat.

Joe Camel never does that.

Advice is free, it's the application that costs.

Comment

-

i also noticed what dirtdobber talked about ... the edges of the tracks look like they would easily grab any weeds or tall grass etc. then wrap them around the axle . i also thought about a piece of belting the needed width on the tub side of the track. instead of pinching the grass between those spaces , it would smash it down below all the axles . the 2 solutions i see are smashing all down as you drive so nothing gets caught up , or a way to shred it as you drive so it does'nt wrap the axle. the 2 collar idea is to shred the grass as you drive . maybe even better on that idea is cut 4 maybe 1'' long pieces of round rod and 2 flat bar pieces the right length . sharpen both flatbars on one edge . you could make this on a rod on your workbench the same size as your axle . clamp the collars the right distance apart with both collars having the top half on the top of the rod and bottom half on bottom of rod . weld the small 1'' rod pieces offset so they are offset from middle of collar but not too close to the collar allen screws so you can tighten and untighten them . then weld the knife flat bar to top of the 1 '' rods with the cutting edge facing toward the front of the machine . now turn the whole thing over and do the same on the other side of the collar . but this time offset the 1'' pieces the opposite way so the blade is not angled the same as the first one , but still with the cutting edge towards the front . the whole point of this is that as you drive each blade cuts in at a opposite angle than the other , which may help really shred the entangled grass . now just unbolt those 2 collar pieces and clamp them on the axle . all this is if you decide it may work of no other solutions do . johnboy

Comment

-

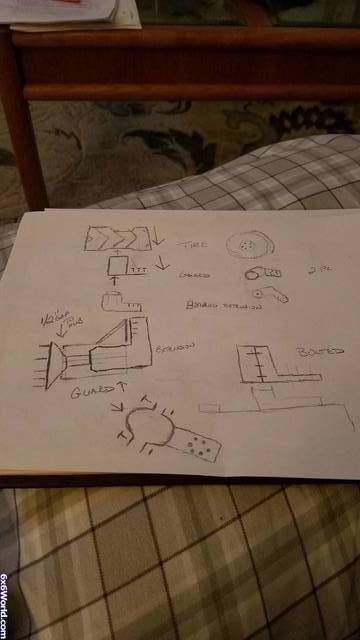

Guys I don't think the blade idea will be beneficial. Delduck said a sickle mower wouldn't even cut this stuff, so a blade with no velocity and nothing backing the vegetation isn't going to cut anything. Jim your idea of using a blade as a wiper of sorts. Delduck I'm going to draw up an illustration of an idea for a fixed axle cover. Stay tuned.

Comment

-

I already did something like that dirtdobber if it shows up, its crude and would need to be 2 piece to be able to clean whatever makes it to the axle. They would only be good for front and rear, just an idea as I have had them in my head for a while but never materialized. Basically like a PTO shield to keep the debris from rotating part.

It does happen with rubber tracks also, I believe it is partly the shape of the bearing extension. If there was a skid from front to rear that also may help.sigpic

My new beer holder spilled some on the trails - in it's hair and down it's throat.

Joe Camel never does that.

Advice is free, it's the application that costs.

Comment

-

a guard type design may work best as you guys have shown . one more idea on that note . take a 2 piece shaft coupler the size of axle . ( mcmaster carr ) it may need to be cut shorter if it's longer than the exposed axle . weld 3 .. 1/2 '' round rod pieces on each half of the coupler so when you look at it from the end it looks like 6 wagon wheel spokes . maybe each would be as long as half the diameter of the tire wheel . on top of each spoke weld a piece of square tubing as long as possible that would be from the edge of the tire to as close to the tub as possible , from the side it will look like t's . take some good gauge sheet metal cut as wide as the length of the t's and long enough to wrap around the whole thing . this would have to be done after the apparatus was clamped to the axle .. which may entail laying the track out of the way . fasten the sheet metal to a few or all 6 of the t's with sheet metal screws or small bolts . now you have a rolling guard that pretty much shields most everything between tire and tub . if it would work , may need 1 for both front axles and one for both back . now it's time to give my brain a rest . johnboy va.

Comment

-

Cup I do things a little different with the phrag then most. In the winter when it’s cold it is brittle so I have from dec to feb to get as much down as possible then I flood the area with sluice gates then when any new shoots start coming up around may I spray the area, that keeps it from growing taller then in September the plant has to make a seed head whether it’s 2’ high or 15’. That’s when we spray again. After the seed head is made it sends all the energy it makes from the sun, to the root, at which time it will take in the herbicide. From April till September it uses the stored energy from the root/ rhizome to make a seed. I’ve worked with the UofD and ducks unlimited on some projects but they are all about the cost per ac, and politics. I deal with people that want waterfowl habitat and not worried about the rest of it. Is far as others doing it, PSE&G in NJ have Argos but they go from point A to point B there not driving all over. The guys that sika deer hunt in MD use the machines to make paths out to the marsh so they can hunt deer but then they are driving over the same paths during the season. The people at marsh masters are great people with tons of knowledge. We have one of there floating swamp excavators BUT to spend $100,000 dollars for the marsh master 2. I’m not ready for that. We have a guy that comes down every year and cuts about 3/4 ac and makes tepee looking things so it dries out then he uses it for roof thatch for teaching displays across the country.

Comment

-

John I had my 80yr +/- farmer over today and he wants to attach a metal pipe to the front only where the phrag gets between the tracks like your saying. I wish I could post pics but it says file to big. I don’t know why they are just pictures from my phone. No different than any other time. It would be nice to push the reply button then take a picture. We’re going to fly the drone in February and put the go pro on the machines. Hopefully I’ll have it figured out by then.

Comment

-

C66C7CBF-74FF-4622-868D-61B99797A842.jpg. Someone please let me know if this worked I don’t see a pic

Comment

-

The grouser design may indeed be part of the problem but not all, using conveyer belting may indeed help with some of the problem.Last edited by ARGOJIM; 12-28-2021, 09:47 PM.sigpic

My new beer holder spilled some on the trails - in it's hair and down it's throat.

Joe Camel never does that.

Advice is free, it's the application that costs.

Comment

Comment