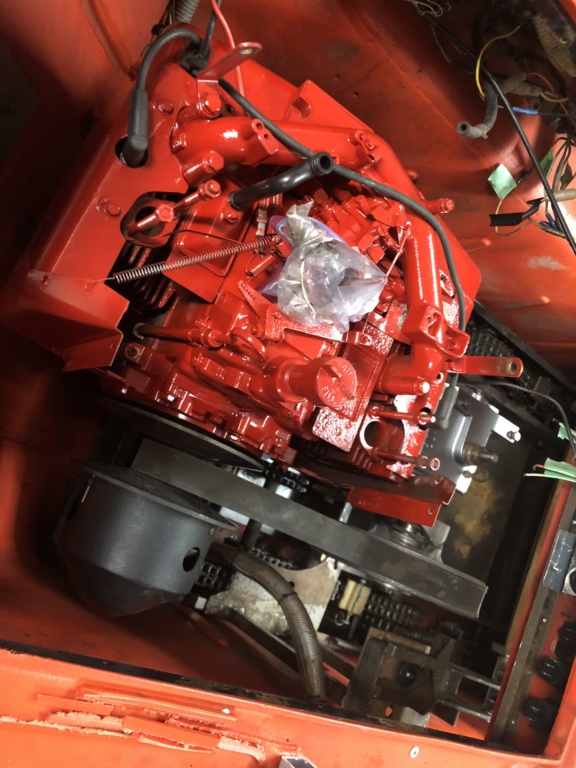

Well, in order to get the outboard low enough to get the cavitaion plate level with the bottom of the hull, some changes to the rear rack were required:

Looks ok and is nearly as strong as it was before. It added another 7” to the rack, but it’s up fairly high so it shouldn’t be a snag hazard when climbing and it’s a relatively small point in the middle so it shouldn’t negatively effect turning. Those pics are with the motor at running height. For land travel, I’m building a vertical sliding outboard mount. It will raise the outboard 18”, which will bring the skeg about 3” below the body split line.

Looks ok and is nearly as strong as it was before. It added another 7” to the rack, but it’s up fairly high so it shouldn’t be a snag hazard when climbing and it’s a relatively small point in the middle so it shouldn’t negatively effect turning. Those pics are with the motor at running height. For land travel, I’m building a vertical sliding outboard mount. It will raise the outboard 18”, which will bring the skeg about 3” below the body split line.

Comment