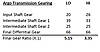

I took that information along with a tooth count on both my Max IV and the Avenger drivetrain to help me determine what tooth count I needed on the intermediate shaft sprocket to mimic the gearing in my Max IV. I have also included the low and high gear of the Avenger transmission with the stock Kohler motor just for comparison since I already had this information.

I am probably going to go with either a 15 tooth or 17 tooth intermediate shaft sprocket. Here are the two spreadsheets showing the difference in gearing and speed between the two. The orange highlighting represents the sprocket that I am going to be changing:

15 tooth sprocket on intermediate shaft:

17 tooth sprocket on intermediate shaft:

Any thoughts on gearing? I could have made a mistake in my calculations somewhere as well. I put these together pretty quickly to keep me from doing these calculations by hand so let me know if something doesn't look right.

Leave a comment: