WOW! That thing looks tough!!!! Good job! One of these years I need to take on the drive and get out to busco, from the videos ive seen, it looks like an awesome time!

Announcement

Collapse

No announcement yet.

2006 Argo Avenger with T20

Collapse

X

-

I thought I would revive this thread and document the next stage of the build. It's been over a year since I initially purchased the Avenger. It took me several months to get it ready for a ride at Busco Beach last April and in doing so, I choose to keep the stock engine and transmission to save time on the build. On its shakedown run in March or April before the Busco ride that I was rushing to get ready, several things went wrong. While on the trails, the spring clip that holds the high gear on the transmission input shaft slid out of its groove and allowed some teeth to get eaten up. Then while limping back to the trailer, one of the brakes quit working and without steering, I was unable to stop from plowing into a tree. I didn't have enough time to get it fixed before the Busco Beach ride so I just parked it and didn't touch it for another several months as my work schedule got busy again.

Now I finally have some free time to start working on it again and I decided to upgrade the motor and hopefully put a T20 in it. I'm in no hurry this time and plan to take the build slow but I would like to finish it in time for next April's Busco Beach ride. If not, it's no big deal but that's the goal for now. So here are the things on the to-do list:

- Build a motor and transmission mount. I am going to copy the stock Avenger powerpack mount as closely as I can so that I can use the existing bolts and frame holes to hopefully save some work. This will also save me from having to build any chain tensioners for the T20 as the chains will be tightened by raising the entire T20 just like you do on the stock Avenger transmission. I have the mount design close to completion. I have designed it in CAD and printed off paper templates. Then I revise and repeat. I wanted to have the T20 output shafts directly over the intermediate shafts in the Avenger but in order to get the T20 all the way behind the stock firewall I will have to have it about 3/4" in front of the intermediate shafts. That should still allow proper chain adjustment.

- Decide on a motor. I'm leaning towards another Bandolero motor but have concerns since it's air cooled and I will have to build some ducting on the intake and exhaust. If I go with a motor other than that, I will need something with similar or greater torque and high RPM to make up for the single speed transmission. I'm not against building up the water cooled Kohler that came with the Avenger but I think having to relocate it will require me to relocate the radiator as well and then I would have to add an electric fan, better charging system, etc. I'm going to wait until I get the T20 located to see how much room I have and decide from there.

- Decide on the gearing. I have loved the gearing on my mid-engine Max IV so I am going to target that same gear ratio for the Avenger. It matches very well with the Bandolero motor torque curve and should have plenty of low end torque.

- Extend the splines on the intermediate shafts. The T20 is wider than the Avenger transmission so I will be extending the splines on the intermediate shafts to allow me to move those gears further outboard.

- Remove the Avenger steering. I initially wanted to keep the handlebar steering and make it work with the T20 but I have concerns of not having the T20 fully engaged while in forward.

- Build laterals and linkage. I have worked on the motor mount enough that I think I have the room I need under it to run the shifting rods. I have kept the T20 as low as I possibly can and plan on either extending the c-channels on the T20 down to meet up with the shift linkage or building some bends into the shift linkage itself. I haven't gotten that far yet and want to get the motor mount built first.

- Build the F-N-R shifter and linkage. I'm undecided on how I want to approach this. The T20 is right in front of the firewall so I could do something as simple as two handles sticking out of the firewall that you push forward or pull backwards. But I will probably end up with something a little more rigid. I am leaning towards a split shifter but have concerns about the torque on the T20 with a counter-rotating 8 wheeler.

- Modify the firewall and floorboard or build new ones. The plastic firewall will not work with the T20 as the recessed foot rests stick into the engine compartment too far. They will hit the secondary CVT. So I will either have to remold it with the heat gun or just build on out of aluminum. The floorboard will not work either as it sits all the way on the bottom of the frame plate where the laterals will have to be mounted. I'm not even worried about these until I get it running.

That's enough of a memory dump for now. I will try to keep this thread updated from here on out as I go so it's not so much information at once. I have some photos I can share later as well.

Comment

-

Wow, man you have a lot of work in front of you. I would leave the split shifter option alone. It takes to much power on a 6x6 and I believe it would over load the T-20 on an 8x8 with ASX tires.

Wow, man you have a lot of work in front of you. I would leave the split shifter option alone. It takes to much power on a 6x6 and I believe it would over load the T-20 on an 8x8 with ASX tires.

I would consider a built 23 horse briggs, but as you stated cooling will be an issue, if you can get it to fit the fuel injected Kohler is a very nice engine. If you decide to go for a for a briggs it be intersting to see a hot rod 8x8 Argo with a 5 or six thousand RPM red line.

I would like to see the look of the 4x4's when they see and hear that Argo coming a half a mile away.

I would like to see the look of the 4x4's when they see and hear that Argo coming a half a mile away.

It will be worth a trip to Busco just to see that machine eat mud!

Comment

-

Just to share my thoughts (right or wrong as they may be)

I have the opposite opinion on the split shift, I think it would be benificial. On my bobcat skid loader you can hear the motor load on turning, being constant throttle hydrostatic machine. If you try to keep one side of wheels stopped and try to turn with only the other side moving, it takes a lot of power as it tries to drag those two stationary tires sideways(yes, only 4 wheels on it). But, If you turn one side forward and the otherside backward, the motor does not have to work as hard to turn the machine. This is somewhat similar (but not exact) to the concept of sliding friction versus static friction.

And since you want to keep the T-20 as low as possible, what is keeping you from flipping the U channels over and running the steering linkage over the top of the transmission?

MAX IV MarkLast edited by MAX IV Mark; 12-09-2012, 03:08 AM.----- \

\

OOO-(

Never argue with an idiot, they will drag you down to their level, then beat you to death with stupidity!

Comment

-

I'm with Mark....split the shifter. You really won't use it much, at least on dry land, but in the water it is fantastic. As far as the added stress of the 8 wheels, the Avenger only has 6 touching, the bands will just slip if it does take too much, and there are tricks to making counter rotation easier. Mark had his fancy sophisticated terms like "static and sliding".....What I know from playing with it, scratching my head, and playing some more is: It IS tough to counter rotate from a standing stop...I'm guessing it is from trying to slide 2 tires each side sideways (4 tires) at the same instant. But if you start moving (just creeping) counter rotation is much easier. Where you really notice the difference is on hard gravel or concrete. Loose/soft dirt or mud counter rotation is easy. And that is with a 16 hp briggs in the tan MaxII I have. With the bigfoot (40 hp) it doesn't matter.

Going over the top of the t-20 with the linkage would work, but would make the sticks backwards....unless you built a simple bracket with a pivot. You could even bolt that to the top of the t-20.

Mike: Dibs on the Kohler if you decide to sell it

I wish I was closer...I'd come over and volunteer some labor.

Comment

-

Thanks for the input. I think I can get it to work with the linkage under the T20. I want to get a mount mocked up and tacked into place and then start moving forward with some of those decisions.

Here's where I currently stand with the engine mount. I began by taking some measurements and sketching what I wanted. I used the stock motor mount as an initial starting point. Then I drew that in CAD. From there I printed it out on paper and used that as a template by cutting it out and actually putting it in the machine. I have done several iterations of this process making slight adjustments as I go. There are so many pieces to this motor mount that I wanted to get it as close as possible on paper first to save me from having to cut metal more than once. I'm sure there are things that I will still have to modify but I have already found many things that needed to be adjusted so I think it has saved me some work already.

Here is the mount I have currently in CAD:

Here is the original Argo mount next to the paper template that I am working with:

Testing the template hole locations in the Argo frame and on the T20 itself:

Finally, here is the T20 just sitting in the Argo in the approximate location it needs to be:

Comment

-

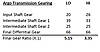

I wanted to post up some of the spreadsheets I've been using while trying to determine what gear ratio I want to use. In trying to keep things simple and do as little work as possible, I am trying to only change the sprocket on the Argo's intermediate shaft to get the gear ratio that I want. I recently opened up my Argo transmission and calculated it's gear ratio by counting teeth. Here is a summary of the stock Avenger transmission gear ratios that came in my Avenger:

I took that information along with a tooth count on both my Max IV and the Avenger drivetrain to help me determine what tooth count I needed on the intermediate shaft sprocket to mimic the gearing in my Max IV. I have also included the low and high gear of the Avenger transmission with the stock Kohler motor just for comparison since I already had this information.

I am probably going to go with either a 15 tooth or 17 tooth intermediate shaft sprocket. Here are the two spreadsheets showing the difference in gearing and speed between the two. The orange highlighting represents the sprocket that I am going to be changing:

15 tooth sprocket on intermediate shaft:

17 tooth sprocket on intermediate shaft:

Any thoughts on gearing? I could have made a mistake in my calculations somewhere as well. I put these together pretty quickly to keep me from doing these calculations by hand so let me know if something doesn't look right.

Comment

-

Mike, first of all, this is an extremely professional conversions ion and I foresee this being an extremely reliable machine because of all the thought and time and effort you're putting into it. I really like your design a lot and I just wanted to add in something for you to consider. Your T-20 cradle looks quite stout, but instead of using the studs on the T-20, I think it would prevent any possible "walking out" of the T-20 from the cradle (which happens on many Hustlers) by just drilling holes in the cradle and securing the T-20 with bolts (and Locktite to keep them from backing out) like on a Max IV. So basically the "U" cutouts for the T-20 mounts are replaced by holes. Also, maybe you could incorporate a provision for a third mounting point that attaches to top the T-20 on each side for extra durability when skid steering (or possibly counter-rotating) 8 wheels. I have some technical specs on the T-20 and gear ratios if you need them as well. Just let me know if there's anything I can do to help you out with this build and sorry if I mentioned something you've already covered......I've been doing so much lately, especially with 6 wheelers, everything seems to just run together. Great work, Mike......keep it up! I'm sure you'll have this monster on the trails in no time."Looks like you have a problem with your 4 wheeler........you're missin' two wheels there"

sigpic

Comment

-

I like your math Mike; I am very impressed that you are able to calculate all the different ratios. Since your dealing with an engine that should have just a little more grunt then the stock Kohler I would go for the 15.45 to one final ratio with a top speed of 27.5 mph. probably as fast as you will ever want or need to go with that machine.

Since you’re dealing with an 8x8 and I might even consider taking it lower since you won't have the low gear on the tranny any more. I have never driven your Max but since you have so much stick time with an engine and a gear ratio so close to what you are already running in the Max it shouldn't be hard to figure out exactly what you are going to need.

:

:

Another Calculation that must be considered is the weight of the tires. I believe the stock Rawhides on a 9" rim are only about 33 pounds each. Having seen the conditions you put that Max Through I would have to believe you are going to need the lower gears, maybe even lower than the ratios you have posted. I would consider something in the range of a 22 mph top speed. Between the engine and the gearing you should have what ever you need for about 90% of the situations that machine will ever see.

Pertaining to the split shifter-In my Argo HD the only time I could use it was on a tight trail with light mud, or in the water, if you tried to use in any mud it over stressed the the entire machine and took an lot of power that abused the rest of the drive train.Last edited by mightymaxIV; 12-10-2012, 01:22 AM.

Comment

-

Mike

My Argo 6x6 Frontier has always ran really hot ,and this I assume is why your engine is water cooled in your argo avenger. Fabricating a two into one or a two into two exhaust will surely help some with the heat issues underneath your hood, but, with the motor sitting so low in the tub, and not enough hot air being able to escape fast enough around the motor, installing a hopped up motor will then add to your over heating issues. Because of so many things falling into the tub around the motor, I have now stopped trail riding with my hood off. The last time that I was out I removed my kick panel instead to see if this made much of a difference in my heat issues, and this made a big difference.

Comment

-

Mike , Ive been looking at this conversion for several years and the mount system looks great. I would add at least two more mount bolts to the t-20. RI added some ears in 2008 that have made the trans stay put.

I have changed the gear ratio on several MAX IIs and Buffalo trucks. These machines get loaded heavy and worked hard and at low speed were hard on belts. The stock ratio from the T-20 to the axles in a buf trk is as follows

trans 15t to jackshaft 27t jackshaft to center axle21t to 30t = 2.57:1 ratio top speed w/23hp kohler about 20 mph??

most common conversion is

trans 15t to jackshaft 34t ( same as MAX IV)then jackshaft down to center axle 21t-30 = 3.235:1 ratio

I have one with a 37 tooth jackshaft with total reduction of 3.52:1. This vehicle with tracks will turn and climb with almost no throtle pressure. Top speed is 14 mph but most of our use is in bad swamp at less than 2mph. Belt life went up to a couple years.

My opinion is use the lower gearing as the Avenger is heaver than an empty buf trk. Add a load and steering at low speed will require a lot of throttle. Keep us posted and thanks for the site!

Comment

-

Thanks for the replies. I won't reply specifically to everyone but I am reading/listening to everything posted. The T20 mount and torque is something that I was and still am concerned about. I first planned on using a brace to another point on the frame similar to the older Max IVs but then I saw Whipper's lock-down plate and stole his idea. If you look below the "U" channels for the T20, there are two more bolt holes. This will allow me to bolt up another plate with four holes to the outside of the mount locking the T20 in place. I'm still not against more bracing and will look into the additional holes.

msafi65, thanks for posting the gear ratios you are playing with. That let me verify some of my calculations.

I was speaking with hydromike and he brought up a good point that I failed to mention. In the spreadsheets I have neglected the gearing of the CVTs. I treated them as a constant because I am going to be using the same setup on the Argo as my Max IV so it was irrelevant to me but I want to point it out to anyone else that tries to use these numbers. I believe the Argo driven clutch is slightly larger than the standard Max and this would skew the numbers in the center two columns but what else skews them is the power robbed by the Argo transmission. So it's not as clear cut as it may seem. Just keep that in mind if anyone else uses these.

Finally, speaking with hydromike made me realize that I may have made a mistake with the CVTs that would effect the top speed calculations. I had assumed that the final gearing of the CVTs was 1:1 but I don't know if this is the case. Does anyone know if the stock Max CVTs are 1:1 final gearing? Again, in the end it isn't important as I am trying to copy the gearing of my Max IV but it would skew the top speed numbers in the spreadsheet.

Edit: OK, for the 780 clutch there are several variations but it seems like the general consensus for calculations is roughly 0.9:1 so the speeds for the T20 machines in the spreadsheet should be higher (divide them by 0.9). I'm not sure about the stock Argo clutch.

Comment

-

That's a creative solution that I wouldn't have thought of. I think I will still extend the splines just to keep the load centered on the sprocket but that is a great idea. Another thing I've been mulling over is the #50 sprocket on the T20. The rest of the drivetrain is either #60 or double 50. It seems wrong to use #50 for the main drive chain delivering power to the rest of the machine.

Comment

Comment